Aluminum Welding Wire - HAOMEI ALUMINUM

- Designation : 5356, 5183

- Diameter : 0.8 - 1.0 -1.2 - 1.6 mm

- Melting Range: 1060 °F– 1175 °F.

- Density: 0.096 lbs/in3

- Tensile Strength: 38 ksi

- Usage: Used for welding 5000 series aluminum base metals, 5086 and lower strength alloys.

- Post Anodizing Color: White.

- Introduction

- Feature

- Application

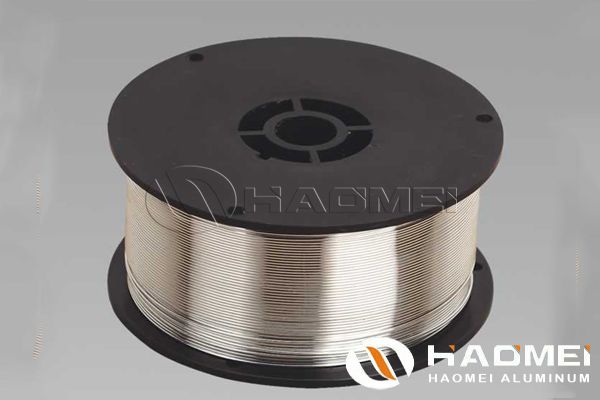

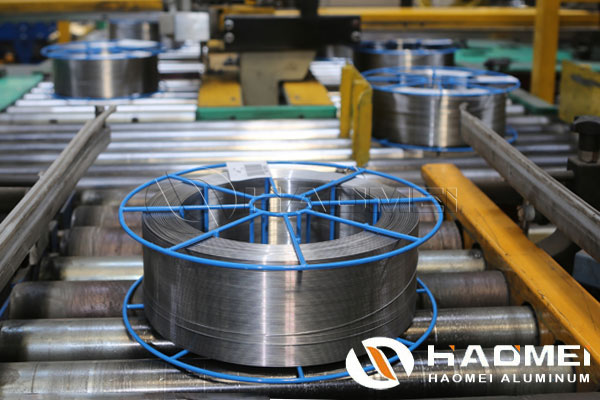

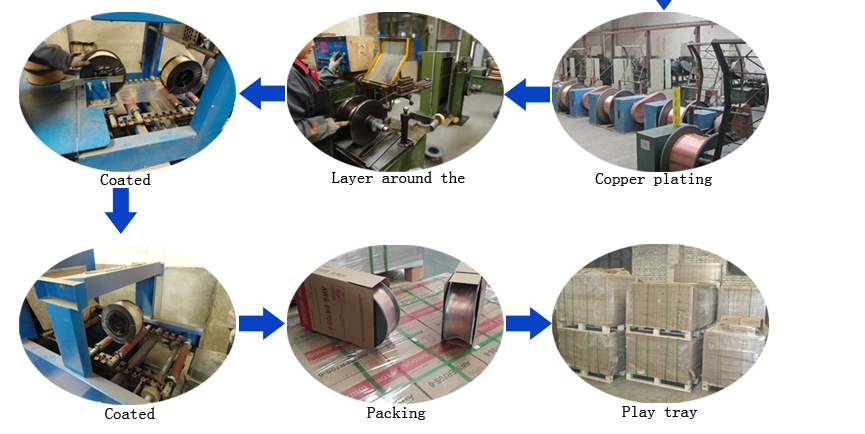

- Pictures

- Video

- Download

Aluminum welding wire creates stronger welds than standard welding wire for aluminum. It is for used aluminum 5050, 5052, 5083, 5454, 5456, 5457 and 5458 marine grade aluminum.

Designation : 5356 aluminum welding wire

Grade : WB

Description : Gas Shield Argon 100%

Diameter : 0.8 - 1.0 -1.2 - 1.6 mm

Welding current : DC

Welding position : All positions for butt welding except vertical downwards (PA,PF,PC,PE)

Remark : N/A.

Melting Range: 1060 °F– 1175 °F.

Density: 0.096 lbs/in3

Tensile Strength: 38 ksi

Usage: Used for welding 5000 series aluminum base metals, 5086 and lower strength alloys.

Post Anodizing Color: White.

Designation : 5183 aluminum welding wire

Grade : WC

Description : Gas Shield Argon 100%

Diameter : 0.8 - 1.0 - 1.2 - 1.6 mm

Welding current : DC

Welding position : All positions for butt welding except vertical downwards (PA,PF,PC,PE)

Remark : N/A.

It is an ER5356, meaning that it contains magnesium as an additive.

What makes the Hobart product stand opposed to the others is that possesses high shear strength and provides huge corrosion resistance. This is very useful for boat welding as you can freely expose the welds to saltwater.

Since it is an ER5356 wire, with it you can weld 5000 series marine grade aluminum base metal. It comes in 0.030-inch or 0.035 diameter and 1 lb spool. It can actually also weld 5086 and lower strength alloys.

It is most commonly used with MIG welding processes and most suitable for working on truck trailers, construction, and boat manufacturing. Furthermore, this welding wire supports various welding positions that include vertical, horizontal, flat, and overhead at a 10 to 15-degree angle.

Why Choose Haomei Aluminum?

- Specialization: We excel in providing top-grade marine grade aluminum profiles.

- Diverse Options: Explore a variety of other grades to suit your specific project requirements.

- Value-added Services: Benefit from efficient sourcing, quick turnaround, and services like precision saw cutting for seamless project integration.

- Reliability: As your trusted aluminum profile distributor, we are committed to meeting your needs promptly and efficiently.

- Certified: Haomei Aluminum is an ISO-certified, CCS,DNV, LR, KR, BV, RINA, and ABS cerificated, family-owned, and operated provider of high-quality specialty metals and alloys.

Features of Aluminum Welding Wire:

Used for 5000 series aluminum alloys.

Aluminum filler with 5% magnesium added.

Brighter weld post anodizing color.

Because of its 5% magnesium content is not suitable for these elevated temperature applications.

Has more shear strength.

Has higher ductility.

Has higher corrosive and saltwater resistance, therefore used for welding boats.

Relatively high shear strength

General-purpose type aluminum alloy

Offers excellent corrosion resistance when exposed to salt water

Available as 0.030 and 0.035″ wire diameter

Slightly brighter post anodizing color

This welding wire is actually best used in very aggressive work environments. It is also more than good in long conduit lengths. Its main usage is in working on structural frames, mainly in the shipbuilding industry, welding automotive bumpers and support, rail cars, trailers, and truck panels. But it is also more than useful in the power industry.