Aluminum Sheet For Boat - Haomei Aluminium

- Alloy: 5083 5086 5052 6061 5454

- Temper: H32, H111, H116, H321

- Shape: Plate, Sheet, Tread Plate

- Application: Marine Ship Building

- Certification: ISO9001, CCS, DNV

- Delivery Time: 20-30 Days

- Introduction

- Feature

- Application

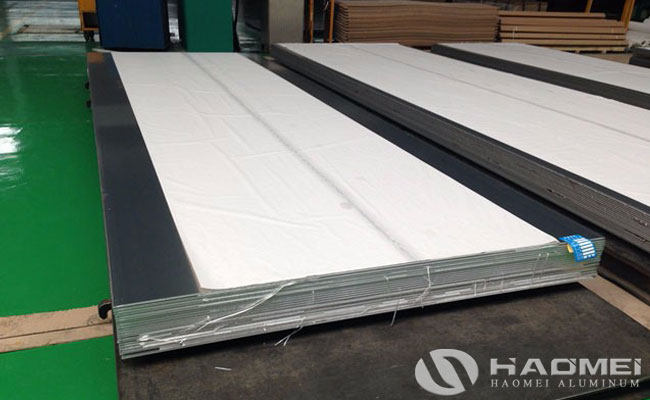

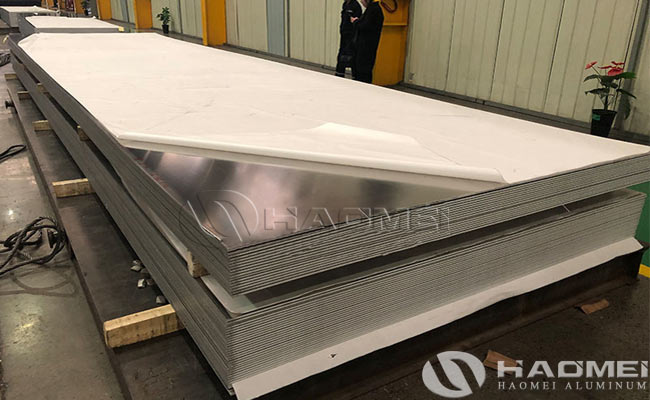

- Pictures

- Video

- Download

Aluminum for boat making belongs to 5000 Al-Mg series alloy. Good cold working performance, good forming performance and corrosion resistance. Marine aluminum alloy is the most widely used anti-rust aluminum. This marine grade aluminium alloy has high strength, especially fatigue resistance, high plasticity and corrosion resistance, and good plasticity when hardened by semi-cold work. The material in H19 state is first oxidized to improve the adhesion and corrosion resistance of the paint, and the two sides are painted after the forming process.

Aluminum sheet for boat making material:

Typical alloy: 5083 5086

Thickness (mm): 0.15-600

Length (mm): 500-16000

Material status: O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H 116, H321

Typical products: aluminum sheets for oxidation, marine sheet metal parts, chemical petroleum storage devices, etc.

Properties of Aluminum For Boats:

Aluminum Grade Temper | General | Yield strength (psi) | Ultimate Tensile Strength (psi) | Workability | Weldability | ||

5052-H32 | Marine grade. Most suited for forming operations, very good corrosion resistance. Suitable for fresh water and trailered boats. | 28,000 | 33,000 12% elong. | Fair | Good | ||

5083-H321 (Interchangeable With: H111 H116) | Marine grade. The highest strength non-heat-treatable aluminum alloy in commercial use. It retains excellent tensile strength in the weld zone. Excellent corrosion resistance. Suitable for salt water or fresh. | 33,000 | 46,000 16% elong. | Good | Excellent | ||

5086-H32 | Marine grade. Medium to high strength non-heat-treatable alloy. More formable than 5083. Excellent corrosion resistance. Most often used to build boat hulls (in addition to 5052 or 6061) due to stress corrosion cracking resistance. Best alloy for salt water. | 30,000 | 42,000 12% elong. | Excellent | Good | ||

6061-T6 | Marine grade, often used as stiffeners to build boat hulls and other components. The most often used aluminum alloy for its strength, heat treatability, workability and weldability. | 40,000 | 45,000 17% elong. | Good | Good | ||

6063-T52 | Softer and lower strength than 6061, good for forming, high surface finish, excellent for anodizing. Good for railings, gunnels etc. where forming is required. | 21,000 | 27,000 | Good | Good | ||

6262-T6511 | Used when significant machining is required, it contains lead and bismuth to partially lubricate the cutting tool. Good strength and corrosion resistance. High surface finish possible. | 27,600 | 31,900 | Excellent | Good | ||

Aluminum sheets for boat building packaging and shipping:

1) Paper clip or film on the aluminum sheet to ensure that the surface of the aluminum sheet is intact without scratches;

2) Plastic or kraft paper package is used to prevent moisture and rain, and to ensure that the aluminum sheet is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China where there is more rain) ;

3) Install wooden pallets and reinforce them with steel belts to avoid collisions during transportation and ensure that the geometry of the aluminum sheet remains unchanged;

4) Export products are packed in wooden boxes and brackets with fumigation marks;

5) Pack according to other packaging requirements of customers.

Performance Advantages of Aluminum Sheet Marine Grade for Boats:

1) It has high plasticity, corrosion resistance, and is suitable for use in marine environments;

2) The surface of the aluminum sheet has no peeling, bubbles, surface roughness and local mechanical damage, and the surface of the aluminum sheet has no cracks, corrosion spots and traces of nitrate;

3) The company has 6 semi-continuous casting production lines, 10 continuous casting and rolling production lines, 44 other large-scale processing equipment, with an annual output of 1 million tons;

The Application of Aluminum Sheets for Boat

1. Marine plate

2. Inner and outer siding

3. Ship Structural Part

4. Side of ship

5. External board of ship bottom

6. Operation room funnel

7. Ship deck