Aluminum-Steel Structural Transition Joints For Shipbuilding

Aluminum-steel structural transition joints are key components for achieving reliable connection between aluminum and steel components and are widely used in the shipbuilding industry. Due to the differences in physical and chemical properties of aluminum and steel, the joint design is intended to ensure effective connection between the two while maintaining the strength and corrosion resistance of the structure.

Technical parameters of aluminum-steel structural transition joints for shipbuilding

- Material: aluminum alloy (such as 5083, 6061, etc.) and carbon steel (such as Q235, Q345, etc.)

- Connection method: welding, bolting, gluing, etc.

- Surface treatment: anodizing, spraying, galvanizing, etc.

Metallurgical connection type of aluminum-steel structural transition joints for shipbuilding

1. Explosive welding transition plate

- Principle:

The impact force generated by the explosion of explosives causes the surface atoms of aluminum and steel to diffuse to form a metallurgical bonding layer (thickness of about 10-50μm).

- Structure:

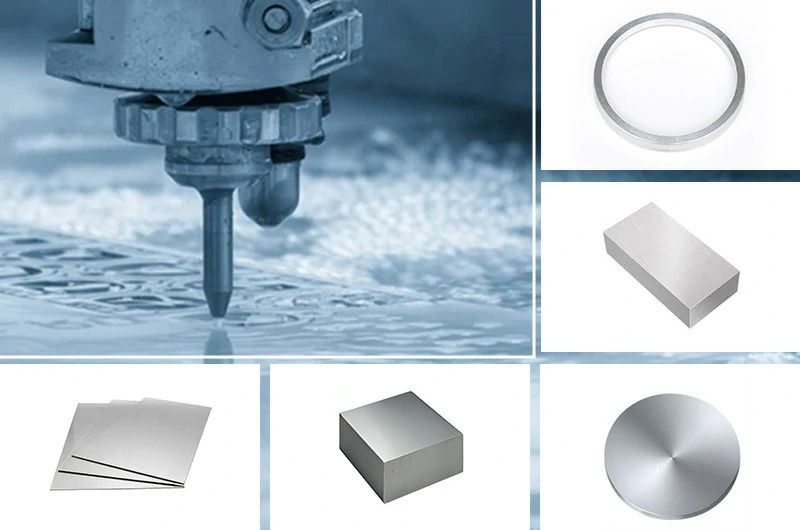

Prefabricated aluminum-steel clad plates (such as 5083 aluminum + Q345 steel), and then cut into joint parts.

- Advantages:

High bonding strength (shear strength ≥150MPa), suitable for main load-bearing structures (such as hull keel connections).

- Case:

The aluminum hull and steel propulsion system bracket of a certain type of high-speed patrol boat are connected by explosive welding transition plate.

2. Friction stir welding (FSW) transition joint

- Process:

Use a rotating stirring head to produce plastic flow at the aluminum-steel interface to avoid the high temperature defects of melting welding.

- Technical points:

An intermediate transition layer (such as copper or zinc) is required to reduce the interfacial reaction activity, and the stirring head material is tungsten alloy.

- Application:

Suitable for long weld connections (such as aluminum decks and steel bulkheads), the tensile strength of the joint can reach more than 80% of the aluminum parent material.

Features of aluminum-steel transition joints for shipbuilding:

- Excellent connection performance:

Advanced connection technology is used to ensure a tight connection between aluminum and steel, which can withstand large loads and stresses.

- Corrosion resistance:

After special surface treatment (such as anodizing, coating, etc.), it effectively prevents electrochemical corrosion and extends the service life of the joint.

- Lightweight design:

The use of aluminum makes the overall structure lighter, reduces the weight of the hull, and improves navigation efficiency.

- Strong adaptability:

Customized solutions can be provided according to different ship designs and use environments to meet various working conditions.

- Easy to install:

The design takes into account the convenience of installation, and with standardized connection methods (such as bolt connection, welding, etc.), it is convenient for engineers to quickly construct.

Aluminum-steel structural transition joints are widely used in:

- Structural connections of merchant ships, yachts and other types of ships.

- The connection between the hull and the superstructure.

- Support and connection of internal facilities of the ship.

Aluminum-steel structural transition joints are an important part of modern shipbuilding technology. With its superior performance and flexible application, they help the efficient development of the shipbuilding industry.