Marine Grade Aluminum Plate Standard Size

The marine grade aluminum plate standard size may vary for different models and applications. Generally speaking, the size of marine grade aluminum plate will be determined according to its application scenarios, the structure and design requirements of the ship. Marine grade aluminum plate has a wide range of application scenarios and is mainly used in ship hulls, characterized by high strength, good corrosion resistance, excellent weldability, good ductility, and can adapt well to the harsh marine environment. In addition, with the reduction of ship weight, marine aluminum plate can also improve the running speed of the ship and bring higher economic benefits.

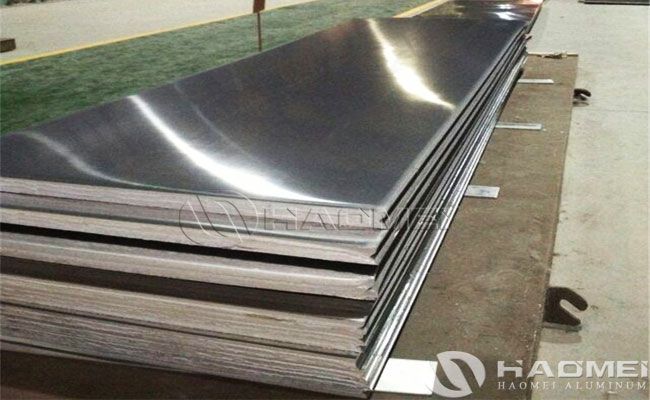

For the common marine grade aluminum plate standard size, common 5052, 5083, 5086, 6061 and other aluminum alloys are used for marine grain aluminum plate, the thickness of marine aluminum plate is generally 2 ~ 15mm, the thickest can be up to 100mm-500mm or more, the width ranges from 100-2650mm, the length ranges from 500-16000mm. The common thicknesses are 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, and the standard size marine plate aluminium are 1.5m*3m, 2m*6m and so on.

Marine grade aluminum plate are materials used to make the hull of a ship, including plates used in the hull, sides, superstructure, and other parts of the ship. This type of marine aluminum sheet is characterized by high corrosion resistance, high plasticity, and light weight, so it is widely used in the shipbuilding industry for the fabrication of various metal structural parts. In addition, 5083 marine grade aluminum plate is commonly used marine aluminum plate, belongs to the aluminum-magnesium alloy, with low density, high toughness, high corrosion resistance and weldability, used in shipbuilding can not only reduce the quality of the ship, but also increase the load capacity, improve the safety and service life of the ship, but also has the economy.

It should be noted that the marine grade aluminum plate standard size also needs to be determined according to the specific application scenarios and design requirements, so it is recommended to consult directly with professional manufacturers or designers.