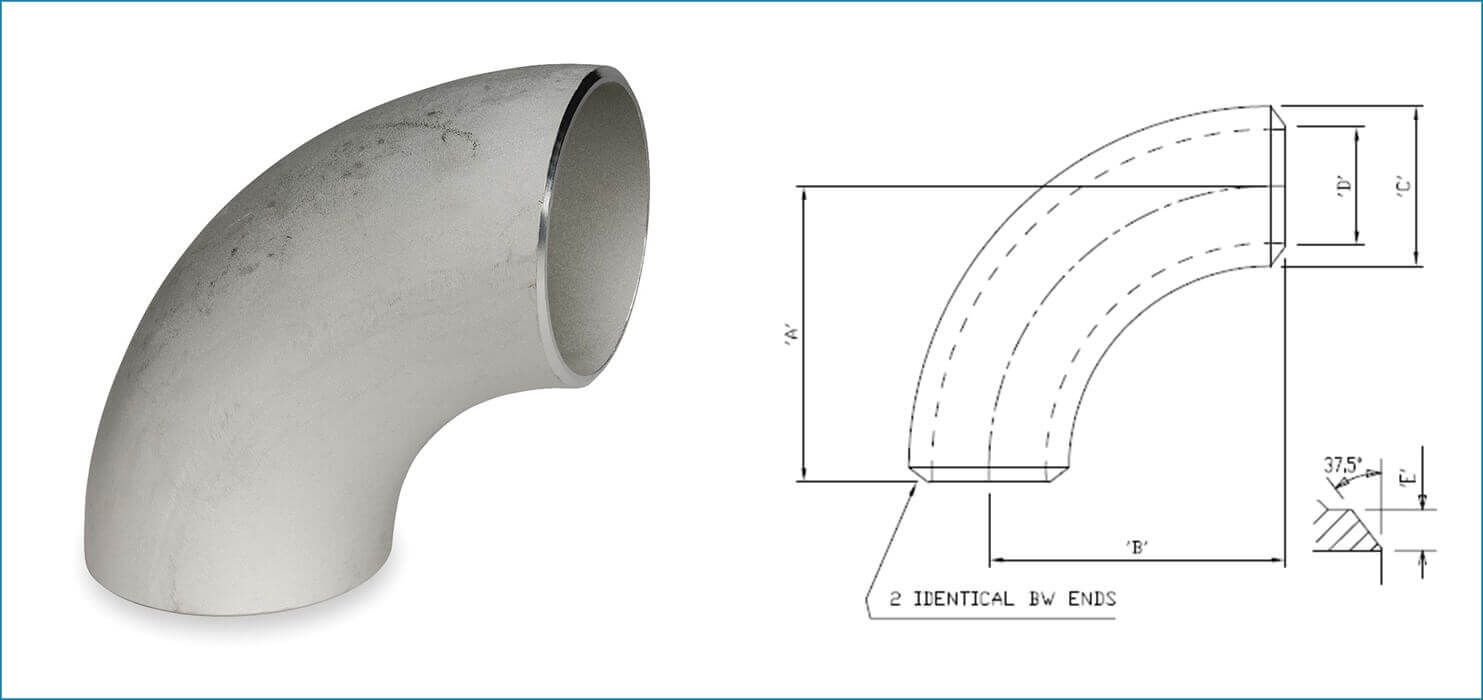

Aluminium Elbow

- Types: Seamless / ERW / Welded / Fabricated Pipe Fittings

- Available Bending: R= 1D, 2D, 3D, 5D, 6D, 8D, 10D or Customized Fittings

- Standards: ASTM B361IASME SB361

- ASTM B241|ASME SB 241

- Introduction

- Feature

- Application

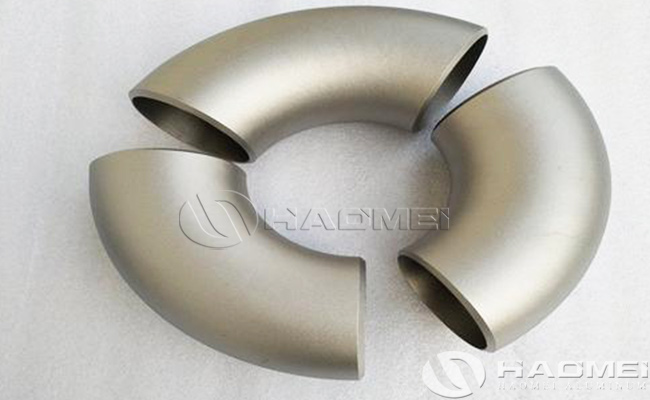

- Pictures

- Video

- Download

Aluminum elbow is a pipe fitting used to change the flow direction of fluid in a piping system. They are usually made of aluminum material, which has the advantages of light weight, corrosion resistance and economical.

Aluminum elbows can be classified according to the bending angle and pipe diameter. Aluminum elbows can be divided into 1060 aluminum elbows, 6061 aluminum elbows, 6063 aluminum elbows, 6082 aluminum elbows, 5083 aluminum elbows, etc.

Aluminium Elbow Product Specification:

Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

Elbow Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

Available Bending | R= 1D, 2D, 3D, 5D, 6D, 8D, 10D or Customized Fittings |

Standards | ASTM B361IASME SB361 ASTM B241|ASME SB 241 |

Export to | Saudi Arabia, Oman, Kuwait, Netherlands, Bahrain, Qatar, UAE, Africa, Nigeria, Mexico, Canada, Venezuela, United States, South Africa, Malaysia, Bangladesh, Singapore, Sri Lanka, Australia, Brazil, France, Italy, South Korea, Poland, Iran, United Kingdom, Turkey, Germany, Belgium |

Types of Aluminum Elbows:

Classified by angle, common types of aluminum elbows include:

45-degree Elbow: The bending angle is 45°, which is used to reduce the resistance of fluid flow and gradually change the direction of the fluid.

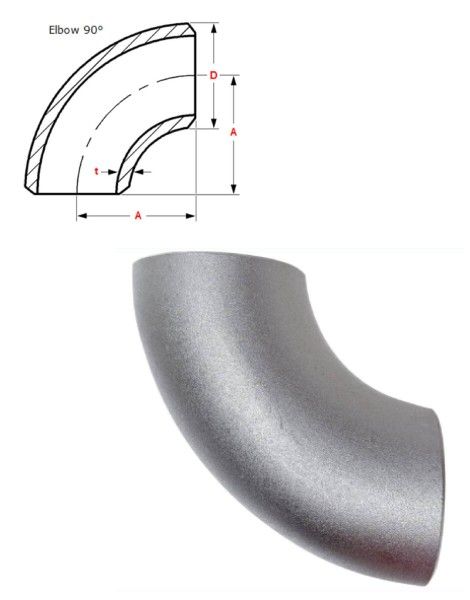

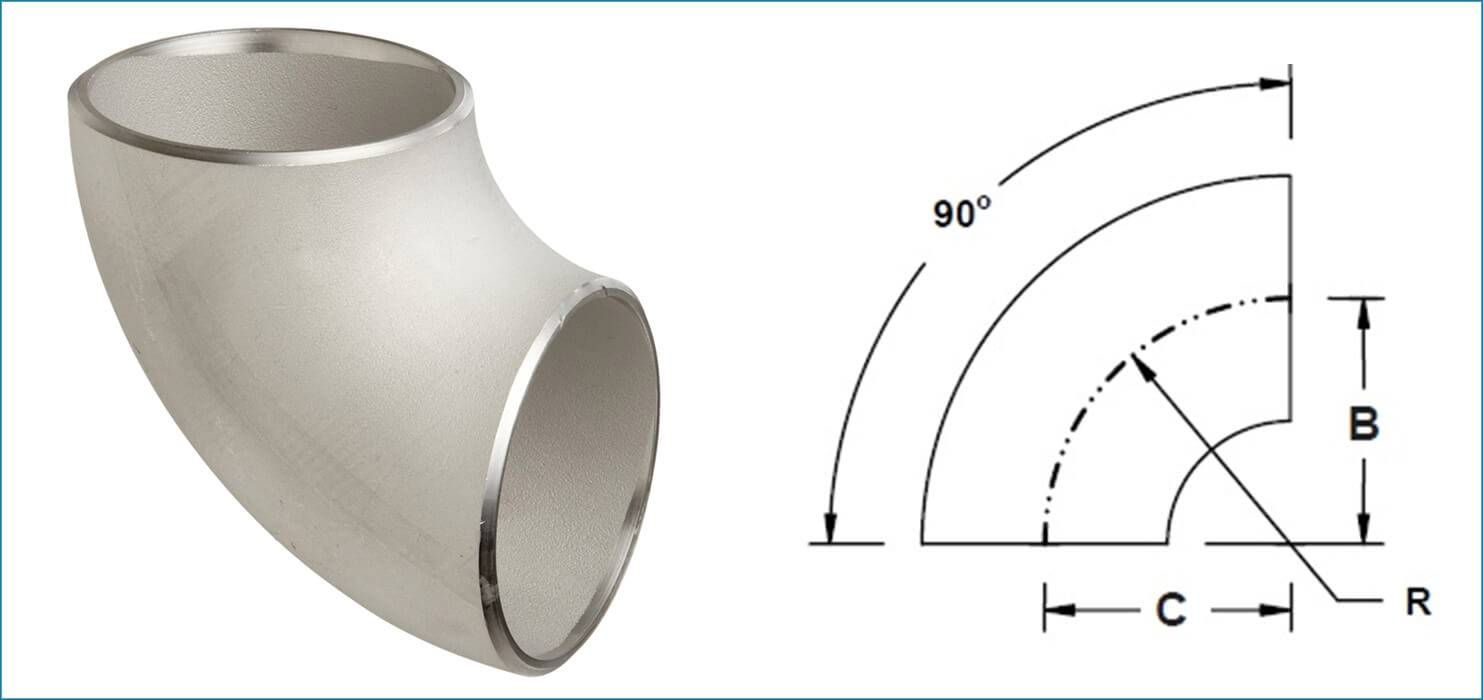

90-degree Elbow: The bending angle is 90°, also known as a right-angle elbow, which is often used in situations where the direction of the pipeline needs to be changed.

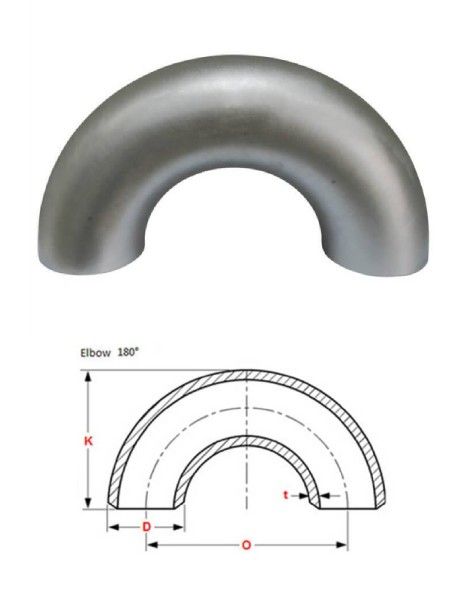

180-degree Elbow: Also known as a U-shaped elbow, the bending angle is 180°, which completely reverses the pipeline and is often used in pipelines that require fluid reflux. Usually designed with a long radius to reduce fluid impact.

In addition to these standard angle elbows, other special angles of aluminum alloy elbows such as 60° are also included according to project needs to meet the needs of specific projects.

Selection suggestions

Scenario requirements | Recommended Angles | Reasons |

Small directional adjustment, low flow resistance | 45° Elbow | Low pressure drop, suitable for high flow system |

Right-angle turns, compact space | 90° Short Radius (SR) | Save installation space |

Complete reverse flow, reduced vibration | 180° Elbow | Buffer fluid impact, extend pipeline life |

Precise layout or special path | Customized Angles | Flexible matching of complex design requirements |

Classification by Bending Radius:

Aluminum elbows are divided into two types: long radius (LR) and short radius (SR) according to the ratio of their bending radius to the pipe diameter (D):

Type | Bending radius (R) | Typical ratio | Description |

Long Radius (LR) | R = 1.5D | Common in low pressure, high flow systems | The elbow has a gentle curvature and a large bending radius |

Short Radius (SR) | R = 1.0D | Suitable for space constrained scenarios | The elbow has a steep curvature and a small bending radius |

Long Radius Elbow (LR):

Flow characteristics: streamlined design, small pressure drop, low fluid resistance, suitable for systems with high flow or need to reduce turbulence.

Installation space: occupies a large space, and a longer pipeline layout needs to be reserved.

Typical applications: chemical pipelines, ventilation systems, liquid delivery pipelines.

Short Radius Elbow (SR):

Flow characteristics: sharper bends, large local pressure drop, and vortexes may be generated, suitable for systems that are not sensitive to pressure drop.

Installation space: compact design, suitable for narrow spaces or pipeline layouts that require frequent turns.

Typical applications: internal piping of equipment, industrial devices with limited space, and temporary piping systems.

Core Advantages of Aluminum Pipe Elbows:

1. Lightweight design

The density of aluminum is only about 1/3 of that of steel (2.7g/cm³), which greatly reduces the weight of the piping system.

2. Excellent corrosion resistance

A dense oxide film (Al₂O₃) is naturally formed on the surface of aluminum, which resists atmospheric, fresh water and weak acid and alkali corrosion.

Strengthening treatment:

Anodizing: Artificially thicken the oxide layer, and the corrosion resistance is increased by 3-5 times.

Powder spraying: Suitable for marine environments (such as desalination plants).

Comparative advantage: Compared with carbon steel, it does not require galvanizing for rust prevention, and the life cycle cost is lower.

3. Excellent thermal conductivity

The thermal conductivity coefficient is 237 W/(m·K), which is about 4 times that of steel. High temperature conditions need to be used with expansion joints to offset thermal expansion.

4. Convenient processing

Process advantages:

Extrusion molding: Complex cross-sections are formed in one go, suitable for customized elbows.

TIG/MIG welding: The weld strength is more than 80% of the parent material, and there is no magnetic interference.

Economical: The processing energy consumption is 40% lower than that of stainless steel, suitable for mass production.

5. Electromagnetic compatibility

Characteristics: non-magnetic material, resistivity 2.65×10⁻⁸Ω·m.

6. Environmental protection and recyclability

Recycling: The energy consumption of aluminum recycling is only 5% of that of ore smelting, and the recycling rate exceeds 95%.

Certification system: It complies with green standards such as LEED and RoHS, and helps achieve carbon neutrality goals.

The Application Scope of Aluminum Elbows includes:

- Plumbing system: used to connect water pipes and change the direction of water flow.

- Refrigeration and air conditioning system: used to adjust the flow direction of refrigerant.

- Industrial pipeline: used to change the flow direction of gas or liquid in various industrial environments.

- Automobile manufacturing: used for engine exhaust system, cooling system, etc.

- Architectural decoration: used in indoor water supply and drainage and outdoor curtain wall support structure.