Threaded/Screwed Flange

- Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- Size: 1/2" (15 NB) to 48" (1200NB)

- Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- BS: BS4504 , BS4504, BS1560, BS10

- Introduction

- Feature

- Application

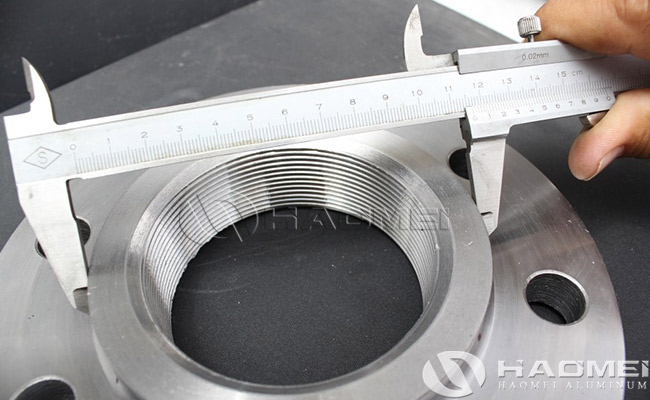

- Pictures

- Video

- Download

What Are Threaded Flanges?

Threaded Flange is a pipe flange that is threaded to the pipe and can be installed without welding, suitable for low pressure, small diameter or frequent disassembly scenarios.

Threaded/Screwed Flanges have threads and can be fitted to pipes that have external threads. Threaded/Screwed Flanges are low priced, fit best for small pipes and can be used in low-pressure applications. They are very beneficial in highly combustible industries where welding is dangerous.

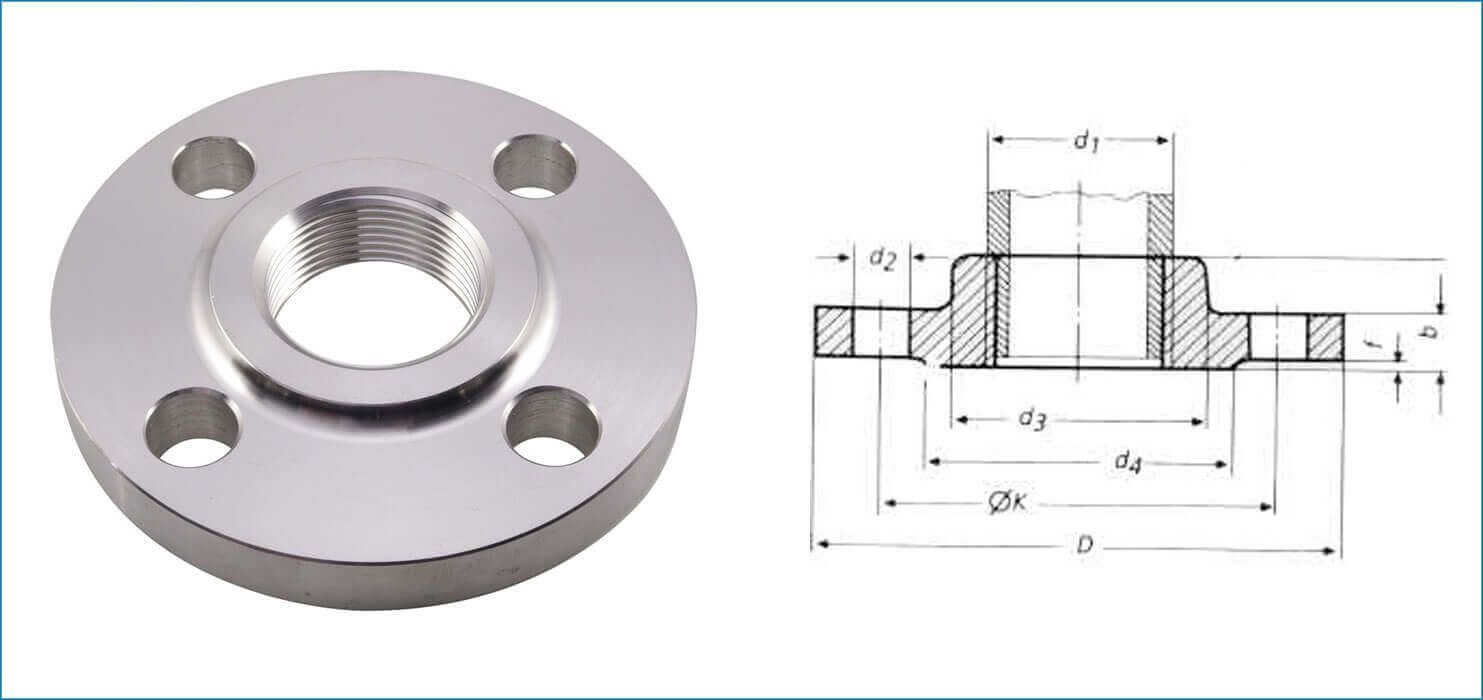

Threaded Flange Structural Features:

- Internal thread design: The flange bore is machined with internal threads (generally tapered thread NPT or parallel thread BSP), which are matched with the pipe external threads for screwing.

- Sealing surface type: common convex (RF), flat (FF) or ring joint surface (RTJ), through the thread sealant or gasket to achieve sealing.

- Weldless connection: relies on threaded occlusion fixing, avoiding the effect of high temperature welding on material properties.

- Flange holes: bolt holes are evenly distributed for easy alignment and fastening with other flanges.

Threaded Flanges Product Specification:

Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

Size | 1/2" (15 NB) to 48" (1200NB) |

Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

BS | BS : BS4504 , BS4504, BS1560, BS10 |

Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Types of Aluminum Threaded Flanges:

Screwed Flanges | Threaded Pipe Flange |

ANSI B16.5 Threaded Flanges | Threaded Flange Dimensions |

ASME B16.5 Screwed Flanges | ANSI B16.5 Class 150 Threaded Flanges |

Threaded Plate Flanges | ASME B16.47 Screwed Flanges |

ANSI B16.5 class 150 Screwed Flanges | ANSI 150 Threaded Flange Distributors |

Threaded Flanges Core Advantages:

- Easy installation: no welding required, suitable for environments where fire is prohibited (e.g. flammable and explosive areas) or temporary piping systems.

- Removability: easy to maintain and reuse, suitable for interfaces that require frequent disassembly (e.g., instrumentation, valve connections).

- Economy: save welding cost and time, especially for small diameter low pressure pipeline.

- Material compatibility: suitable for materials with poor weldability (e.g. cast iron, certain alloys).

Applications of Aluminum Threaded Flanges:

- Low pressure utility systems: water treatment, fire hoses, compressed air piping.

- Gas distribution: low-pressure natural gas or liquefied petroleum gas (LPG) piping.

- Chemical industry: low-pressure transportation of non-corrosive media (need to cooperate with sealant).

- Instrumentation and equipment connection: pressure gauges, sensors, interfaces for small pumps and valves.

- Special environment: mines, oil and gas wellheads and other places that require explosion-proof.