Weld Neck Flange

- Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- Size: 1/2" (15 NB) to 48" (1200NB)

- Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- BS : BS4504 , BS4504, BS1560, BS10

- Introduction

- Feature

- Application

- Pictures

- Video

- Download

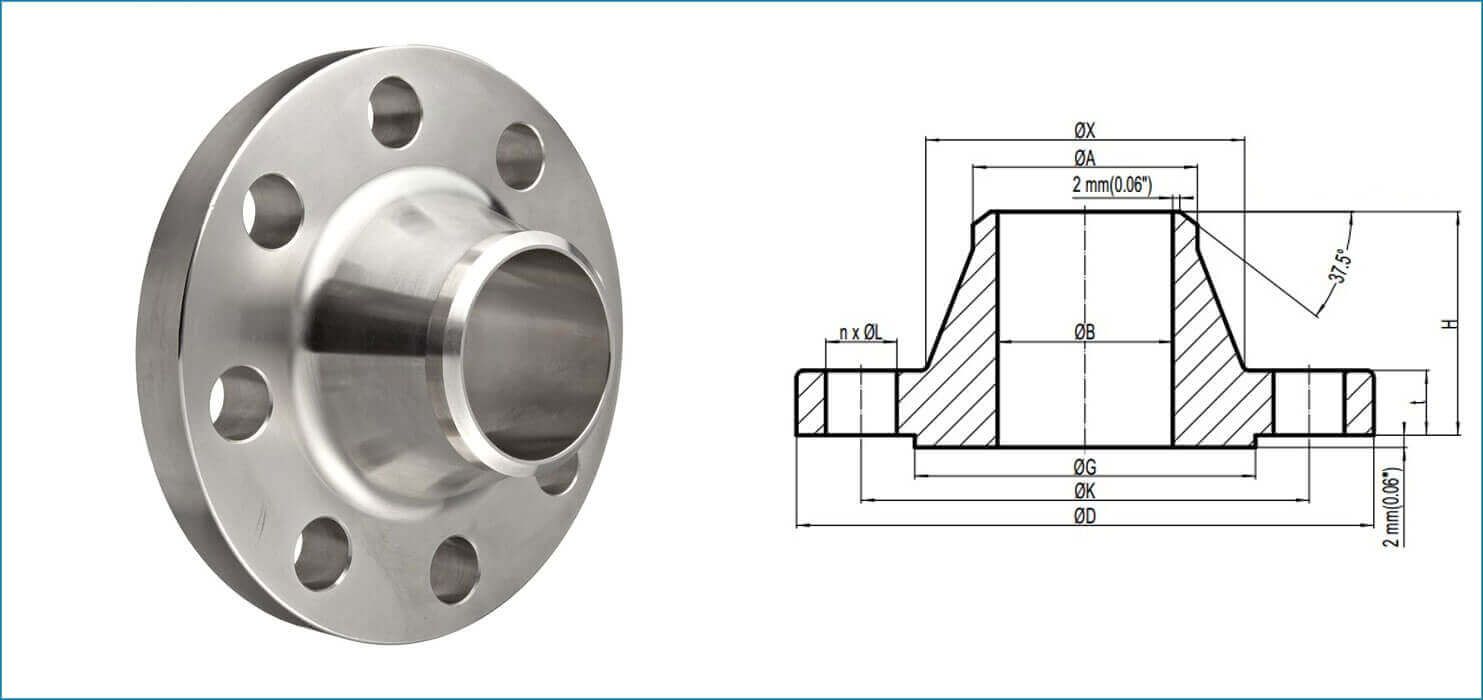

What Are Weld Neck Flanges?

Weld neck flange is a high-strength pipe connection flange, connected to the pipe by butt welding, suitable for high pressure, high temperature or severe working conditions.

These flanges are seamlessly welded onto the end of a pipe, creating a robust and leak-proof connection. The unique design of the weld neck flange provides superior strength and stress distribution, making it an ideal choice for high-pressure, high-temperature, and high-impact applications.

Weld Neck Flange Structural Features:

- Long neck conical transition: with a long conical neck, butt welding with the pipe, the neck thickness gradually transitions to the wall thickness of the pipe, optimizing stress distribution.

- Welding method: After the pipe end is processed and beveled, it is double-sided welded with the flange neck (inside and outside weld) to ensure the connection strength.

- Sealing surface type: common convex surface (RF), ring joint surface (RTJ), or concave-convex surface (MFM), adapting to high-pressure sealing needs.

- Flange holes: evenly spaced bolt holes for precise alignment with paired flanges.

Weld Neck Flanges Product Specification:

Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

Size | 1/2" (15 NB) to 48" (1200NB) |

Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

BS | BS4504 , BS4504, BS1560, BS10 |

Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Types of Aluminum Weld Neck Flanges:

Weld Neck Raised Face Flange | Raised Faced Weld Neck Flanges |

ANSI B16.5 Weld Neck Flanges | Weld Neck Flange Dimensions |

ASME B16.5 WNRF Flanges | ANSI B16.5 Class 150 Weld Neck Flanges |

High Quality WNRF Flanges Manufacturer | Flat Faced Weld Neck Flanges |

ANSI 150 Weld Neck Flange | WNRF Flange |

Weld Neck Flanges Core Advantages:

- High strength and sealing: double-sided welding and neck design can withstand high pressure, high temperature and mechanical vibration.

- Stress Dispersion: Tapered necks smooth the transition of stresses and reduce stress concentrations at the pipe-flange connection.

- Applicable to extreme working conditions: high temperature resistance (such as steam systems), corrosion resistance (with high-grade materials) and fatigue resistance.

- Long life: Suitable for industrial systems with long-term stable operation.

Applications of Weld Neck Flanges:

The inherent properties of WNRF flanges, such as their ability to withstand extreme conditions(pressures and temperatures), make them indispensable in various applications. They are prevalently used in oil and gas, petrochemicals, water treatment, and power generation industries. The design ensures a smooth flow of fluids, minimizing turbulence and erosion.

- Oil and gas: high-pressure transportation pipelines, refinery reaction units, submarine pipelines.

- Chemical industry: high-pressure vessel connections for strongly corrosive media (e.g. acids, alkalis).

- Power and energy: high-temperature steam pipeline (power plant), nuclear power plant main cooling system.

- Long-distance pipeline: oil and gas transmission main line, need to withstand high pressure and geological displacement.