Socket Weld Flange

- Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- Size: 1/2" (15 NB) to 48" (1200NB)

- Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- BS: BS4504 , BS4504, BS1560, BS10

- Introduction

- Feature

- Application

- Pictures

- Video

- Download

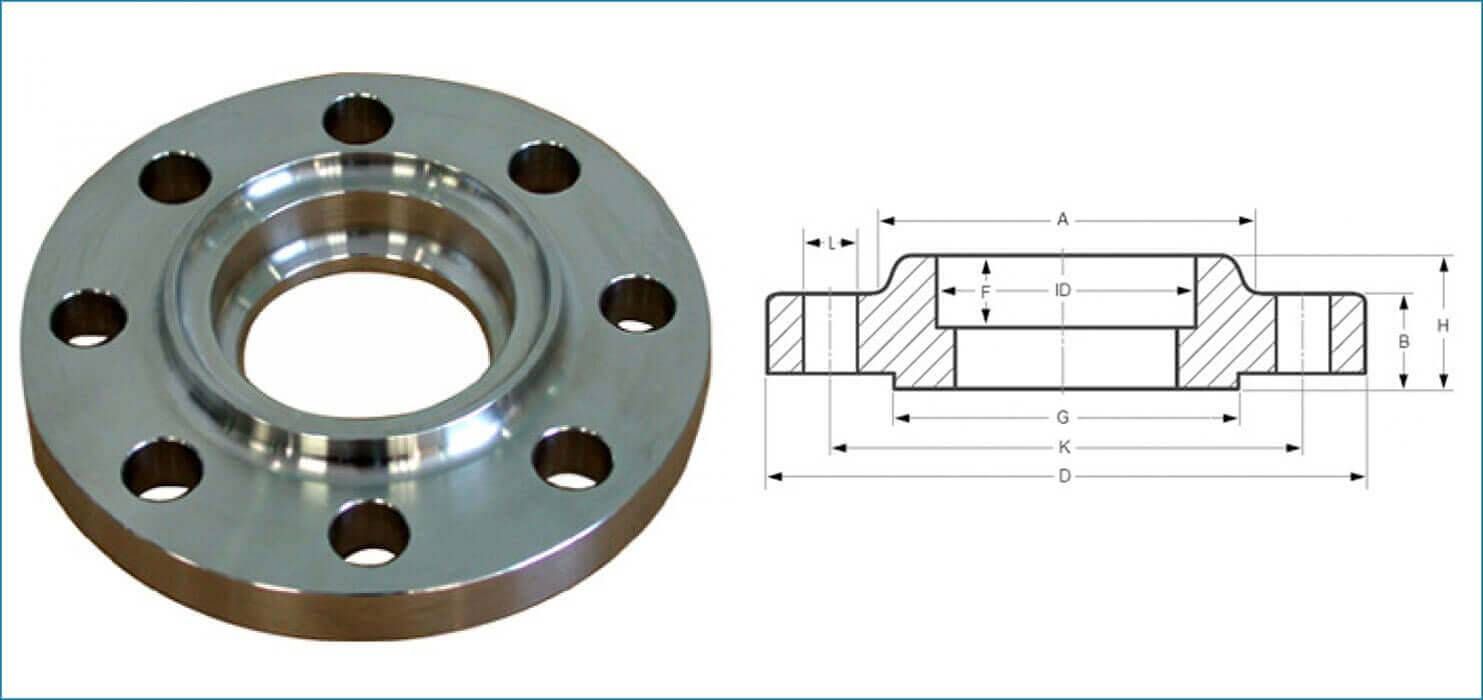

What Are Socket Weld Flanges?

Socket weld flange is a flange for small diameter high pressure piping systems, which is welded by inserting the pipe into the flange socket and is suitable for scenarios that require a high degree of leak tightness.

Socket Weld flanges balance strength with ease of installation through socket welding, making them ideal for small-diameter, high-pressure systems.

Socket Weld Flange Structural Features:

- Socket design: The flange bore has a groove (socket), which is welded after the pipe end is inserted to form a firm connection.

- Single-side welding: After the pipe is inserted, fillet welding is performed on the outside of the contact surface between the flange and the pipe, no beveling is required.

- Sealing surface type: common convex surface (RF) or ring joint surface (RTJ), suitable for high pressure sealing.

- Gap reservation: After the pipe is inserted, a gap of about 1.6mm needs to be reserved with the bottom of the socket to compensate for the stress caused by thermal expansion.

Socket Weld Flanges Product Specification:

Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

Size | 1/2" (15 NB) to 48" (1200NB) |

Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

BS | BS : BS4504 , BS4504, BS1560, BS10 |

Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Types of Aluminum Socket Weld Flanges:

Socket Weld Raised Face Flange | Raised Faced Socket Weld Flanges |

ANSI B16.5 Socket Weld Flanges | Socket Weld Flange Dimensions |

ASME B16.5 SWRF Flanges | ANSI B16.5 Class 150 Socket Weld Flanges |

High Quality SWRF Flanges Manufacturer | Flat Faced Socket Weld Flanges |

ANSI 150 Socket Weld Flange | SWRF Flange |

Socket Weld Flanges Core Advantages:

- High-strength sealing: welding combined with socket structure, sealing is better than threaded connection, suitable for small diameter and high pressure system.

- Convenient installation: no need for complex bevel processing, welding operation is simple, suitable for space-constrained compact environment.

- Anti-vibration performance: high strength of weld seam, resistant to mechanical vibration and shock load.

- Economy: Compared with butt-welding weld neck flanges, less material is used, suitable for small pipe diameter scenarios.

Applications of Aluminum Socket Weld Flanges:

- High-pressure fluid system: steam, gas, hydraulic oil and other high-pressure small-diameter pipeline (such as instrumentation lines, sampling lines).

- Chemical and petrochemical industry: corrosive media small diameter connection (need to match the corrosion-resistant materials such as stainless steel).

- Power industry: boiler water piping, high pressure steam instrumentation lines.

- Valve and pump connection: need frequent maintenance or compact installation of the interface position.