Slip On Flange

- Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- Size: 1/2" (15 NB) to 48" (1200NB)

- Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- BS: BS4504 , BS4504, BS1560, BS10

- Introduction

- Feature

- Application

- Pictures

- Video

- Download

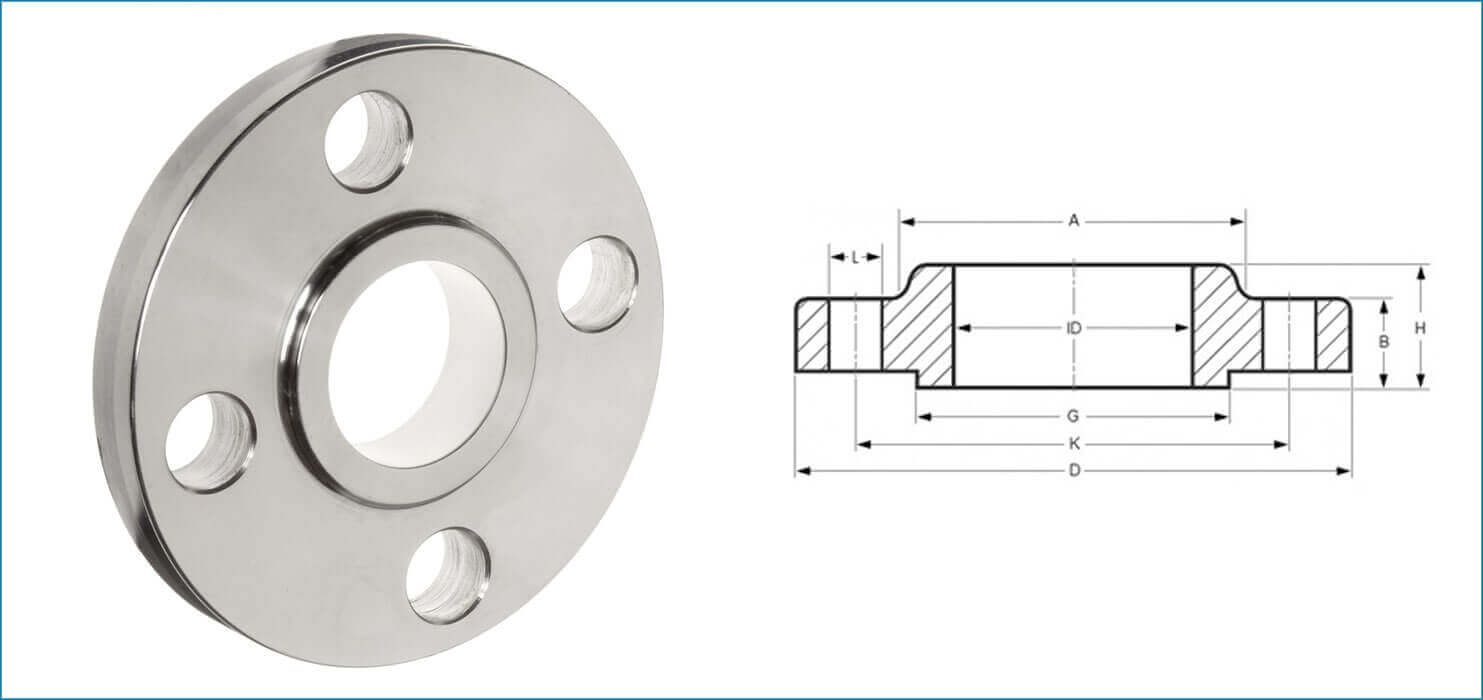

What Are Slip On Flanges?

Slip on flange is a common pipe connection flange that is fixed to the pipe or equipment by flat welding. Slip On flanges strike a balance between cost and performance, making them ideal for low and medium pressure piping systems.

Made from aluminum alloy, aluminum slip on flanges are built to withstand various environmental conditions, ensuring longevity and durability. The primary characteristic of these flanges is their ability to easily slip over the end of a pipe. Once positioned, they are welded inside and outside, creating a secure and sturdy joint. This dual welding process not only enhances the strength of the connection but also significantly reduces the risks of leaks, making these flanges an essential component in any piping system.

Slip On Flange Structural Features:

- Short Neck Design: With a short conical neck that matches the outside diameter of the pipe to provide structural support.

- Welding method: The flange bore is set outside the pipe and is welded by an external fillet weld (usually one side only) without the need for beveling.

- Sealing surface type: common flat surface (FF), convex surface (RF) or concave-convex surface (MFM), selected according to requirements.

- Flange holes: bolt holes are evenly spaced for easy alignment and installation.

Slip On Flanges Product Specification:

Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

Size | 1/2" (15 NB) to 48" (1200NB) |

Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

BS | BS4504 , BS4504, BS1560, BS10 |

Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Types of Aluminum Slip On Flanges:

Slip on Raised Face Flange | Raised Faced Slip-On Flanges | |

ANSI B16.5 Slip On Flanges | Slip on Flange Dimensions | |

ASME B16.5 SORF Flanges | ANSI B16.5 Class 150 Slip-On Flanges | |

High Quality SORF Flanges Manufacturer | Flat Faced Slip-On Flanges | |

ANSI 150 Slip on Flange | SORF Flange |

Slip On Flanges Core Advantages:

- Easy installation: no need to precisely align pipe ends, suitable for space-constrained scenarios.

- Low cost: less material than Weld Neck, simple welding process.

- Wide applicability: suitable for systems with frequent disassembly and maintenance, such as pump and valve connections.

- Stress distribution: Neck transition reduces localized stress concentration and is superior to flat flanges.

Applications of Aluminum Slip On Flanges:

- Water treatment and chemical industries: aluminum flanges are used in these industries to connect various pipes and equipment to handle liquids and gases.

- Refrigeration and air conditioning systems: aluminum flanges are used in this field to connect components such as compressors, condensers, evaporators, etc.

- Industrial Production Lines: In automated production lines, aluminum flanges are used to connect pipes of different equipment to transport materials or perform other operations.

- Automotive Manufacturing: In automotive manufacturing, aluminum flanges are used for engine cooling systems, turbocharging systems, etc.

- Construction Engineering: In building water supply and drainage and fire fighting systems, aluminum flanges are used to connect large pipes.