Aluminum Pipe Fittings

- Standards : ASTM B361, B361

- Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

- Size : 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated)

- Bending Radius : R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

- Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

- Introduction

- Feature

- Application

- Pictures

- Video

- Download

Aluminium fittings are commonly used in plumbing and piping systems due to their lightweight and corrosion-resistant properties. We Haomei Aluminum are the reliable and the most trusted pipe fitting manufacturer who providing wide range of aluminum pipe fittings of premium quality and are highly durable.

We provide various types of aluminum alloy fittings such as 5083, 5086, 6061, 7075 etc. These fittings are leak proof with life long warranty without compromising with the strength of these fittings. Along with all other qualities, our fittings are highly appreciated for their superior finish with sophisticated and sleek design.

These aluminium pipe fittings are available in different sizes, shapes, thickness and other dimensions as per allotted by our prestigious clients. We have a well stocked supply of flanges, elbows, tees, reducers and pipe end caps as well as a large selection for a wide variety of customer requirements.

Aluminium Pipe Fittings Product:

Specifications | Aluminium |

Dimension | ASME/ ANSI B16.9 | ASME B16.28 | MSS-SP-43 | BS1560 | BS4504 | BS10 |

Grade | 6063, 6082 T6/ T651, 6061T6/ T651, 5083, 5052, 5086, 1100, 2024, 7075, 2014 |

Size Ranges | ½” NB to 24″ NB in Schedule 10s, 40s, 80s, 160s, XXS. |

Bending Radius | Radius=1 D, 2D, 3 D, 5D, 6D, 8 D, 10D or Custom |

Types | Welded | Seamless | Fabricated |

Process of Manufacturing | Push, Press, Cast, Forge. |

Thickness of Fitting | SCH10, SCH 20, SCH30, STD SCH40, SCH80, SCH60, XS, SCH100, SCH 120, SCH140, SCH 160, XXS available with NACE MR 01-75 |

Size Range | Seamless Butt-Weld Fitting: From 1/2″ - 10″ |

Types of Aluminum Pipe Fittings:

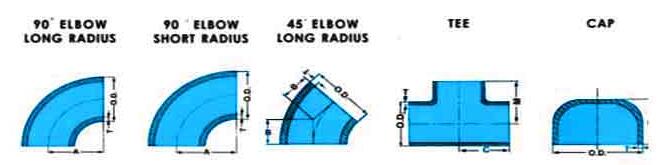

The aluminum pipe fittings usually refer to factory-made wrought aluminum and aluminum-alloy welding fittings conforming to standard specification ASTM B361. The term "welding fittings" applies to butt-welding or socket-end-welding parts. It includes a variety of fitting types such as 90° & 45° elbow, 180° return bend, reducer, tee, cross, cap, and other types made to the dimensional requirements specified by ASME B16.9 and ASME B16.11.

Designs | Types |

Flanges | Slip On, Blind, Plate, Weld Neck, Threaded, Socked Weld, Lap Joint |

Elbows | 45, 90, 180 Deg, Long & Short Radius |

Tees | Equal & Unequal |

Reducers | Concentric & Eccentric |

Pipe End Caps | Different Size and Shapes |

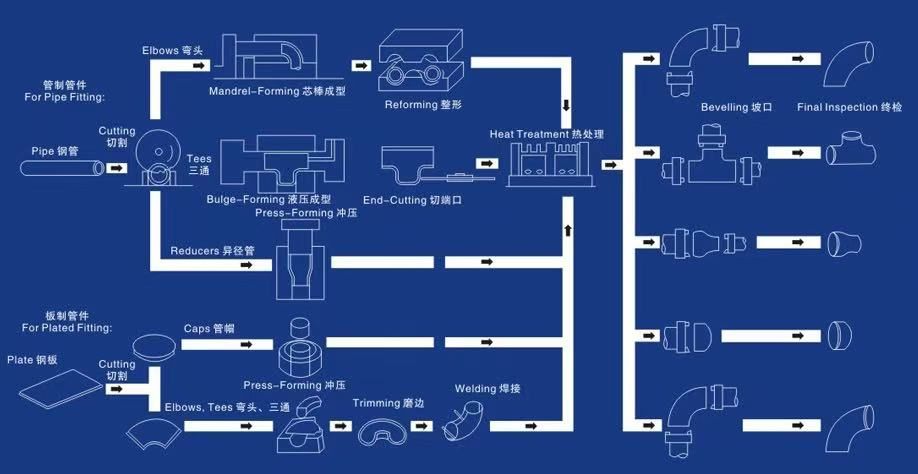

How does Aluminum Pipe Fittings Processed?

Characteristics of the Aluminum Pipe Fittings:

- Wide Selection: We offer one of the widest selections of aluminum pipe fittings , providing customers with a diverse range of options to meet their specific needs.

- High Quality: The aluminum pipe fittings provided by us are of superior quality, ensuring durability and long-lasting performance.

- Easy Installation: The aluminum pipe fittings are designed for easy installation. Their lightweight nature and user-friendly design make them quick and convenient to install, reducing labor costs and saving time during system setup or modifications.

- Durability: Aluminum fittings are known for their durability. They can withstand high pressures and temperature variations, ensuring long-lasting performance and minimizing the need for frequent replacements or repairs.

- Low Maintenance: The corrosion-resistant properties of aluminum fittings make them low maintenance. They require minimal upkeep and are less prone to rust or degradation, resulting in reduced maintenance costs and downtime.

Aluminum pipe fittings are used in several critical systems in the shipbuilding industry due to their lightweight, corrosion-resistant, and high-strength properties.

Application areas include:

1. Fuel delivery systems: aluminum fittings are used to connect fuel lines to ensure tightness and corrosion resistance.

2. Cooling systems: aluminum fittings may be used for cooling pipes in marine engines and equipment, as they require good thermal conductivity and corrosion resistance.

3. Hydraulic systems: high-pressure hydraulic piping may require high-strength aluminum fittings, such as the butt-welded fittings mentioned on page .

4. Seawater treatment systems: such as desalination or ballast water systems, aluminum fittings are resistant to seawater corrosion and are suitable for long-term use.

5. Structural support: some aluminum fittings may be used in ship structures or support frames, taking advantage of the lightweight and high strength properties of aluminum.