Plate Flange

- Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

- Size: 1/2" (15 NB) to 48" (1200NB)

- Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- BS: BS4504 , BS4504, BS1560, BS10

- Introduction

- Feature

- Application

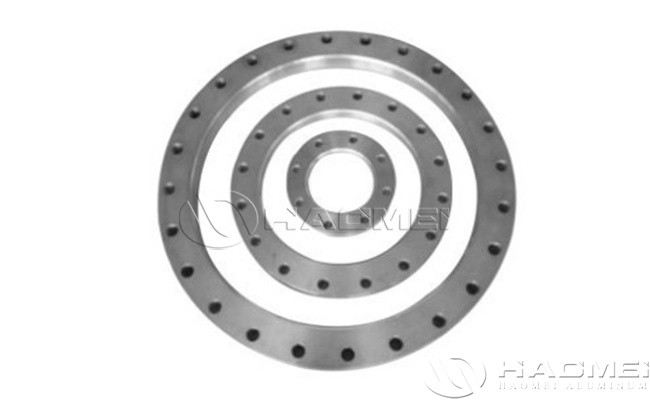

- Pictures

- Video

- Download

What Are Plate Flanges?

Plate Flange is a simple flange type, usually machined from a flat plate and connected directly to the pipeline by fillet welding, suitable for low-pressure, non-critical piping systems.

Plate Flanges can range from 1/2 inch to 48 inches in the nominal bore. They are typically used for pipes with a small diameter and a large bore. These flanges may be pressed on or threaded. Depending on their purpose, they can be used for both high and low-pressure applications.

We produce the best quality B16.5 Plate Flanges that are compliant with global flange standards, free from any cracks and deformities, due to which they last longer and provide an extended service lifespan.

Plate Flange is a common choice for low-pressure, low-cost piping systems due to its economy and simplicity, but in high-pressure, high-temperature or critical systems Weld Neck or Socket Weld flanges are preferred.

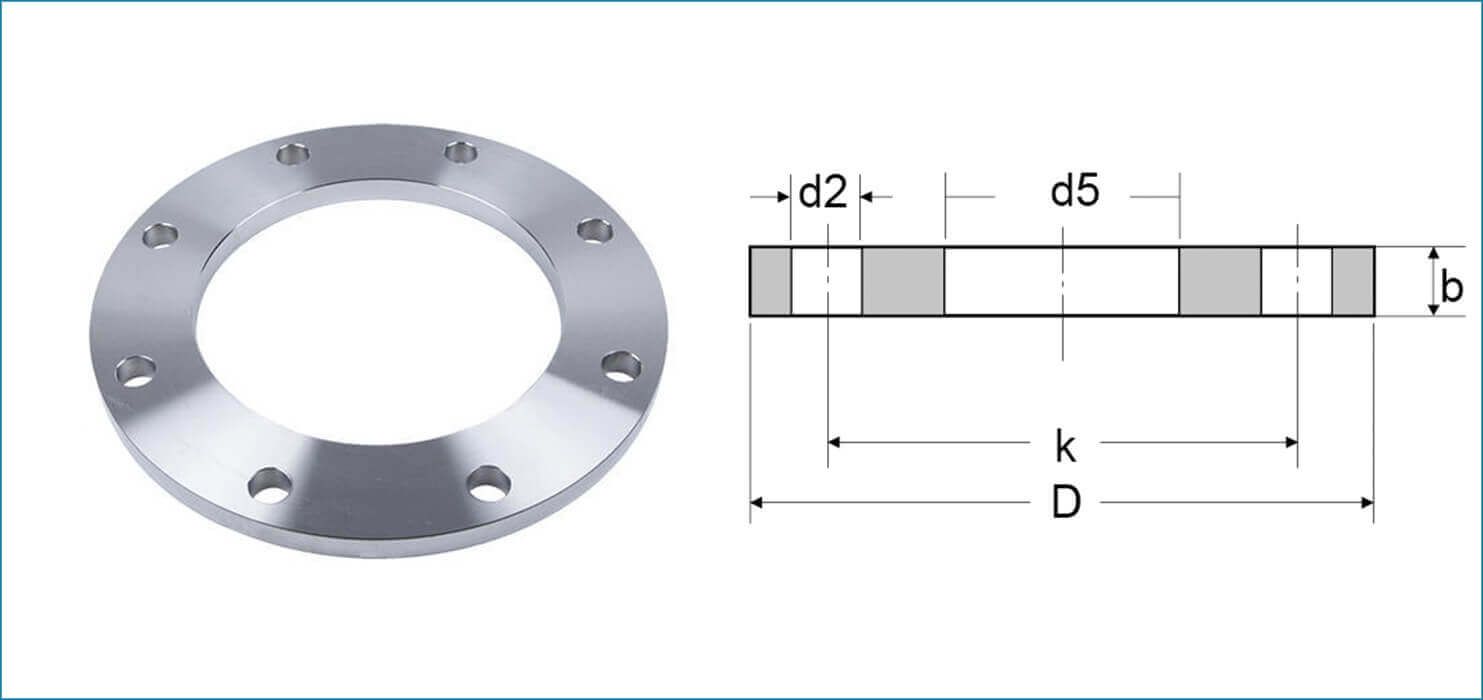

Plate Flange Structural Features:

- Flat plate design: no neck transition, overall flat disc structure, uniform thickness, center hole diameter matches the pipe OD.

- Welding method: After the pipe is inserted into the inner hole of the flange, it is welded by single-sided or double-sided fillet weld on the outside (no beveling is required).

- Sealing surface type: mostly flat (FF) or convex (RF), sealing depends on gasket fit.

- Distribution of bolt holes: Uniformly distributed bolt holes around the edges for fastening in alignment with other flanges.

Plate Flanges Product Specification:

Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

Size | 1/2" (15 NB) to 48" (1200NB) |

Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

BS | BS : BS4504 , BS4504, BS1560, BS10 |

Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Types of Aluminum Plate Flanges:

Plate Pipe Flange | Raised Faced Slip-On Flanges |

ANSI B16.5 Plate Flanges | Plate Flange Dimensions |

ASME B16.5 Plate Flanges | ANSI B16.5 Class 150 Plate Flanges |

High Quality Plate Flanges Manufacturer | Plate Flanges Suppliers |

ANSI 150 Plate Flange | Flat Faced Plate Flanges |

Plate Flanges Core Advantages:

- Low cost: simple structure, low material usage, low processing cost.

- Convenient installation: no need for complex welding process or beveling, suitable for rapid construction.

- Lightweight: light weight, easy to carry and install, especially suitable for large-diameter low-pressure pipelines.

- Strong versatility: suitable for non-corrosive, non-extreme working conditions of the general fluid system.

Applications of Aluminum Plate Flanges:

- Low-pressure water systems: building water supply and drainage, fire-fighting piping, irrigation systems.

- Ventilation and Air Conditioning (HVAC): air delivery piping connections.

- Low pressure industrial piping: cooling water circulation, compressed air piping.

- Temporary facilities: temporary piping for construction sites, test system connections.

- Non-critical systems: scenarios with low requirements for sealing and pressure resistance.