Equal/Reducing Tee

- Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

- Size : 1/2"NB TO 48"NB IN

- Type : Seamless / ERW / Welded / Fabricated

- Manufacturing process: Push, Forge, Press, Cast, etc.

- Introduction

- Feature

- Application

- Pictures

- Video

- Download

Aluminum tee is a pipe fitting used to divide a main pipe into two or three branch pipes, usually made of aluminum. We are a leading certified manufacturer, supplier and exporter of quality tee pipe fittings, for various application purposes for industries across the globe.

Tee Fittings are commonly suitable for providing a strong connection for intricate pipeline assemblies that help to provide a proper flow of fluids in multiple directions.

As one of the largest manufacturers with years of experience and proven skills, we provide products for various industries which adhere to the best industry standards and can provide the best performance and reliability.

Tee Fittings are suited to petrochemicals, oil and gas, water, power and construction industries. These tees are appropriate for creating or eliminating paths in the system and provide a 90 degree connection to pipes.

Tee Fittings are also available in different sizes and types to fit several applications, contributing to clients receiving high efficiency and longevity. Aluminum tees can be of two types: equal type and reducing type.

- Equal tee: Also known as straight tees, the diameter of one pipe is different from the diameters of the other two pipes, usually used to change the direction of the fluid.

-Reducing tee: Also known as unequal tee, the diameters of the main pipe and the branch pipe are different, suitable for occasions where the direction of the fluid needs to be changed and the flow rate is large.

Equal and Reducing Tee Specification:

Size Range | 1/2"NB TO 48"NB IN |

Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

Thickness | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

Form | Equal Tee, Pipe Tee, Butt weld Tee, Barred Tee, Lateral Tee. Unequal Tee, Reducing Tee, Pipe Tee, Butt weld Unequal Tee. |

Manufacturing process | Push, Forge, Press, Cast, etc. |

Standards | ASTM B361IASME SB361 ASTM B241|ASME SB 241 |

Export to | Saudi Arabia, Oman, Kuwait, Netherlands, Bahrain, Qatar, UAE, Africa, Nigeria, Mexico, Canada, Venezuela, United States, South Africa, Malaysia, Bangladesh, Singapore, Sri Lanka, Australia, Brazil, France, Italy, South Korea, Poland, Iran, United Kingdom, Turkey, Germany, Belgium |

Types of Aluminum Tees:

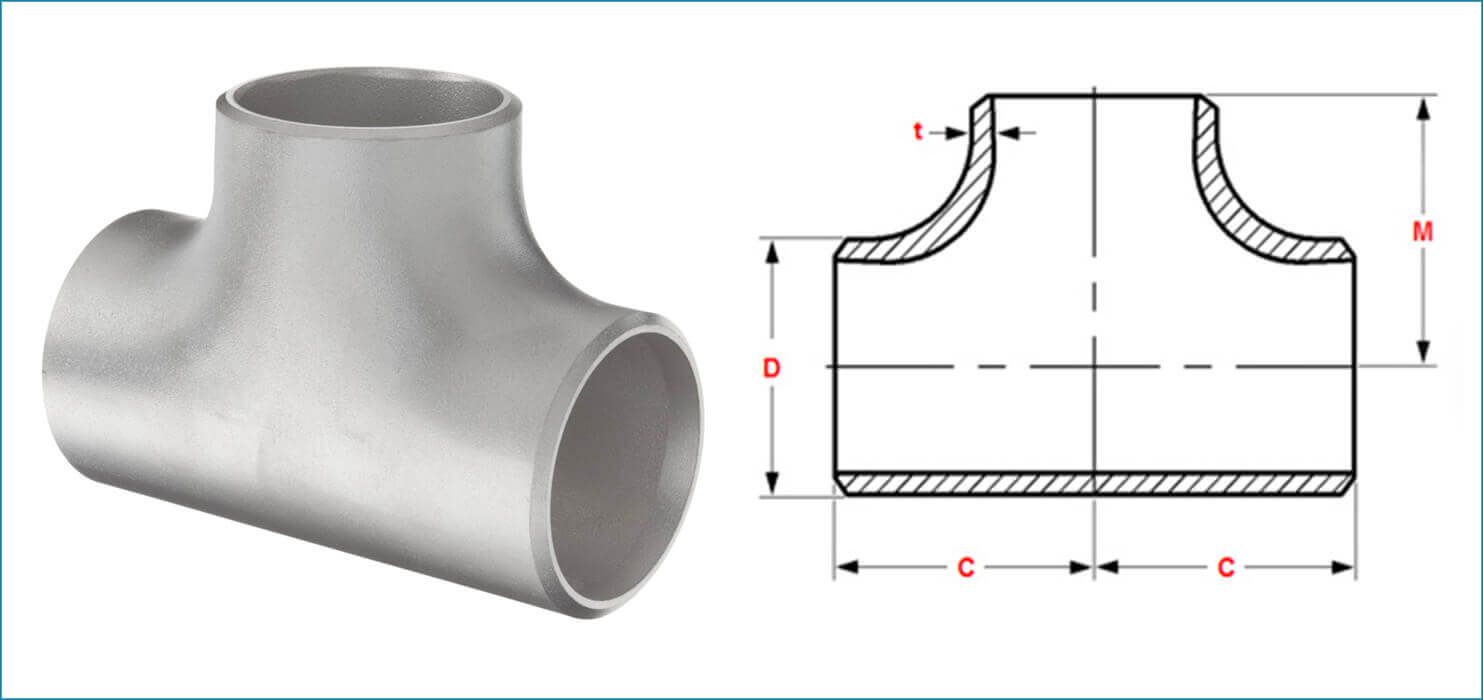

1. Equal tee (equal diameter tee fittings)

Characteristics: Three connections (one main and two branches) have the same diameter.

Application Scenario:

Piping systems that require uniform diversion or merging (e.g., branch piping with the same flow rate).

Commonly used in heating, ventilation and air conditioning (HVAC), water supply systems, hydraulic systems, and other scenes that do not have special requirements for flow distribution.

Advantage: symmetrical structure, low fluid resistance, simple installation.

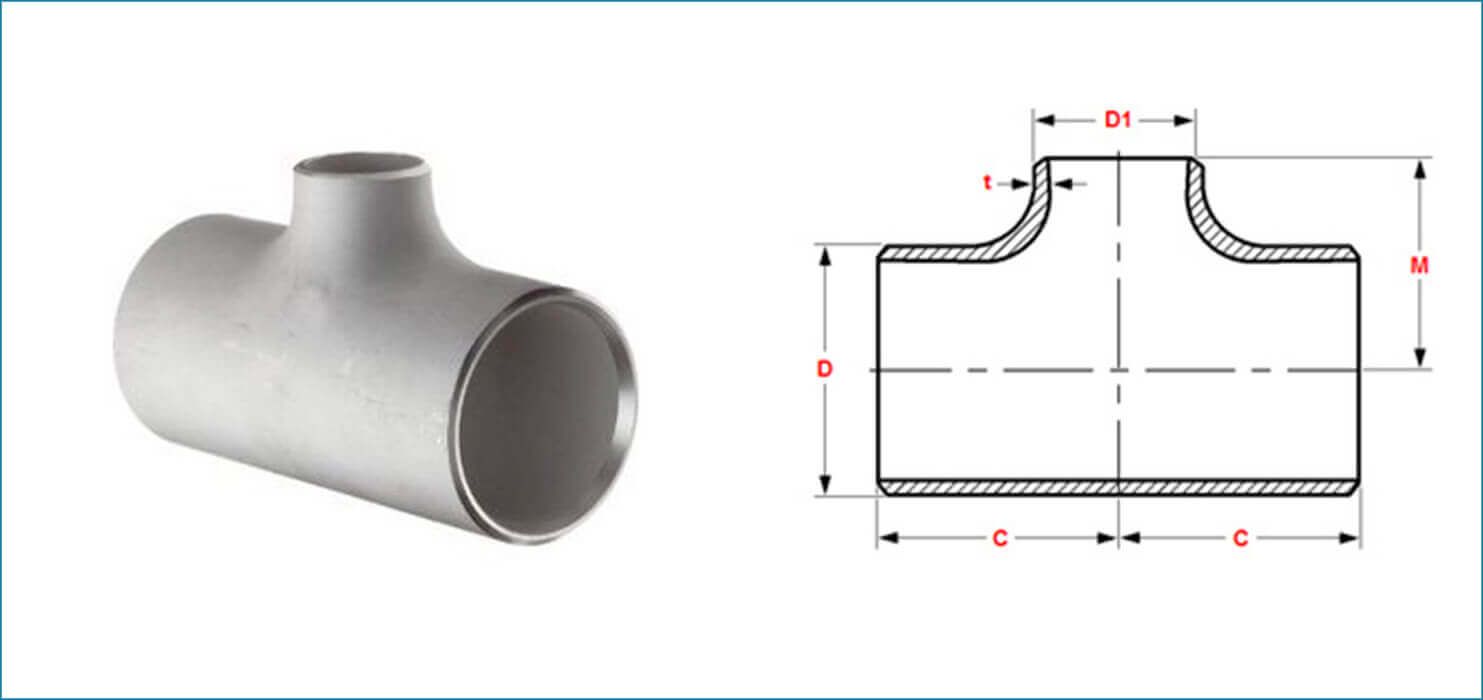

2. Reducing tee (unequal tee fittings)

Characteristics: at least one branch pipe with a different diameter from the main pipe.

Application Scenario:

Systems where branch line flow or pressure needs to be adjusted (e.g., reducing branch pipe diameter to increase flow rate).

Suitable for chemical, petroleum, natural gas and other fields requiring complex flow control.

Advantage: High flexibility to adapt to the connection needs of different pipe diameters.

Equal Tee vs Reducing Tee:

Comparison items | Equal tee | Reducing tee |

Main Features | Main pipe and two branch pipes of the same diameter (D = d₁ = d₂) | At least one branch pipe with a different diameter than the main pipe (D ≠ d₁ or D ≠ d₂) |

Application Scenarios | Scenarios requiring uniform flow separation/combination (e.g., HVAC, water supply systems) | Scenarios requiring flow or pressure adjustment (e.g., chemical, petroleum, natural gas pipelines) |

Advantage | Low fluid resistance, symmetrical structure, easy installation | Flexible adjustment of branch flow or pressure to suit different pipe diameters |

Structural Differences | Symmetrical design, consistent size of three-end connections | Asymmetrical design with at least one connection of a different size than the main pipe. |

Examples of application scenarios | Air conditioning refrigerant distribution, fire fighting pipe branching | Complex piping systems where branch pipes need to be reduced (e.g. to increase flow rate) or enlarged (e.g. to reduce pressure loss) |

Available Types of Aluminum Tee Fitting:

Butt Weld Pipe Tee Fitting | Equal Tee |

ASME B16.9 Butt weld Aluminum Tee | Reducing Tee |

Unequal Tee Fittings | Buttweld Equal Tee |

Aluminum Tee Fittings | Buttweld Reducing Tee |

High Quality Tee Fitting Manufacturer | Aluminum Equal Tee |

Aluminum Tee Suppliers | Equal Tee Manufacturer |

High Quality Equal Tee | High Quality Reducing Tee |

Aluminum Tee Fittings Core Advantages:

- Lightweight: The density of aluminum is only 1/3 that of steel, which significantly reduces the weight of piping systems, making it suitable for use in weight-sensitive applications such as aerospace and automotive.

- Corrosion resistance: Aluminum is naturally resistant to atmospheric corrosion due to the dense oxide film (Al₂O₃) that forms easily on the surface, which can be further enhanced by anodizing.

- Excellent thermal conductivity: High thermal conductivity (about 237 W/m-K), suitable for heat exchange scenarios such as radiators and cooling systems.

- Good processability: Aluminum is highly ductile and can be easily formed into complex structures through extrusion, stamping, casting and other processes.

- Non-magnetic: Suitable for electronic equipment, medical instruments and other environments that are sensitive to magnetic fields.

- Cost-effective: Raw material prices are lower than copper and stainless steel, and low processing energy consumption makes it suitable for mass production.

- Environmentally friendly and recyclable: Aluminum is 100% recyclable, in line with the trend of green manufacturing.

Application of Aluminum Tees:

- Plumbing system: connect water pipes to branch or merge water flow.

- Refrigeration and air conditioning system: used to distribute refrigerant or change flow direction.

- Industrial production line: used to transport various materials in automated production lines.

- Automobile manufacturing: used for engine cooling systems, oil systems, etc.

- Building drainage system: used to collect multiple drainage branches into the main drainage pipe.