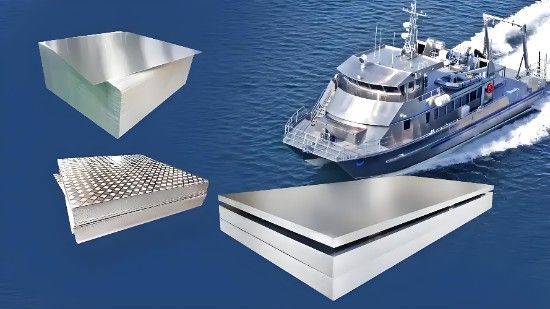

ASTM B928 Aluminum 5059 H321 Plate For Marine Service

ASTM B928 is a standard developed by the American Society for Testing and Materials (ASTM), which mainly involves the application of aluminum alloys in marine environments, especially aluminum alloy materials used in marine facilities and ships. 5059 aluminum alloy is one of the ASTM B928 standard specifications, it is known for its high strength, good welding performance and corrosion resistance. ASTM B928 aluminum 5059 h321 plate is widely used in marine environments such as shipbuilding and marine engineering.

Basic characteristics of 5059 H321 aluminum alloy plate

1. Chemical composition and alloy characteristics

- 5059 aluminum alloy belongs to aluminum-magnesium alloy with a high magnesium content (usually between 4.5% and 5.5%). By adding magnesium to form a strengthening phase, the strength and corrosion resistance of the material are significantly improved.

- H321 temper means that after solution treatment, cold working (deformation of about 2% to 5%) and incomplete annealing, the material has better plasticity and stress corrosion resistance while maintaining a certain strength.

2. Physical and Mechanical Properties

- Low density: (about 2.66 g/cm³) can effectively reduce the weight of the hull, improve speed and fuel efficiency.

- Tensile strength: 310 - 345 MPa in H321 state, higher than 5083-H321 aluminum plate (about 275 - 305 MPa), suitable for high-stress structural parts.

- Elongation: Usually 12% - 16%, better than 5083-H321 (8% - 12%), indicating better processing formability.

- Corrosion resistance: In seawater environment, the pitting potential of 5059 aluminum alloy is higher than 5083, and it has stronger resistance to localized corrosion.

Performance requirements in accordance with ASTM B928:

1. Mechanical properties

ASTM B928 has clear provisions for the mechanical properties of marine aluminum alloy plates. 5059-H321 must meet the following requirements:

- Tensile strength ≥ 310 MPa

- Yield strength ≥ 205 MPa

- Elongation ≥ 12%

These indicators ensure that the material has sufficient safety when subjected to dynamic loads in ship structures.

2. Corrosion resistance test

It is necessary to pass salt spray tests (such as ASTM B117) and seawater immersion tests to verify its corrosion resistance in marine environments. The high magnesium content of marine grade 5059 aluminum alloy forms a dense oxide film on its surface, which effectively resists chloride ion corrosion.

3. Welding performance

The welded joints of 5059-H321 plates must meet the following requirements:

- Weld strength ≥ 80% of the parent material strength

- Crack resistance: no tendency to thermal cracks, suitable for MIG, TIG and other welding processes.

Application advantages of 5059-H321 aluminum plates in shipbuilding:

1. Structural parts application

- Hull keel and ribs: High strength and corrosion resistance make it the preferred material to replace 5083, especially suitable for lightweight design of high-speed boats.

- Deck and bulkhead: Good formability supports complex curved surface processing, reduces the number of welded joints, and improves structural reliability.

2. Corrosion resistance advantage

- In the seawater splash zone, the pitting resistance of 5059-H321 is 20% - 30% higher than that of 5083-H321, significantly extending the maintenance cycle of the hull.

- Suitable for parts immersed in seawater for a long time, such as rudder blades, propeller shaft brackets, etc.

3. Processing and welding convenience

- Cold processing performance: H321 state allows 10% - 15% cold deformation, suitable for bending, stamping and other processes.

- Welding compatibility: When welding with aluminum alloys such as 5083 and 5456, no special welding materials are required, reducing manufacturing costs.

Therefore, ASTM B928 aluminum 5059 h321 plate is an aluminum alloy plate specially designed for marine applications, with the above mentioned properties and processing conditions, it is suitable for the manufacture of ships and other offshore structures, where corrosion resistance and material stability are very important considerations.