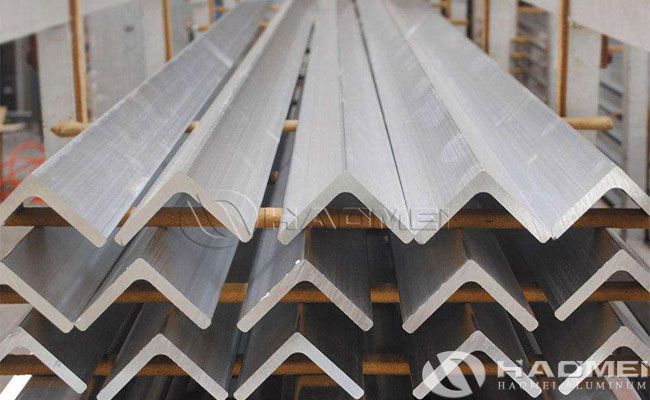

Aluminium Angle Bar Marine Grade 5086

In modern ship construction, choosing the right material is crucial. 5086 marine grade aluminum alloy, as one of them, has taken its place in the shipbuilding industry due to its excellent corrosion resistance and good weldability. In particular, aluminium angle bar marine grade 5086 not only provides structural support for vessels, but also ensures safe and efficient navigation. Marine grade 5086 aluminum angle bar stands out in the harsh marine environment mainly due to its unique alloy composition. This grade of aluminum alloy contains magnesium as the primary alloying element, with small amounts of other elements added to enhance performance. This combination gives marine grade aluminum alloy 5086 excellent corrosion resistance, especially in seawater and atmospheric environments. In addition, it has a high strength-to-weight ratio, which reduces the overall weight of the hull while ensuring structural strength, thus improving fuel efficiency and load-carrying capacity.

The aluminium angle bar marine grade 5086 offer by Haomei Aluminum mainly have data listed below:

Section specification: Mainstream 120×80×8mm L-shape, 100×100×10mm equal leg aluminum angle bar, thickness tolerance ±0.1mm.

Classification society certification: DNV GL, ABS, CCS, LR, RINA

Grain boundary corrosion potential up to -0.78V (ASTM G67 standard)

Tensile strength ≥ 270MPa, fatigue life over 10^7 cycles

Characteristics and performance advantages of aluminium angle bar marine grade 5086:

- Marine grade corrosion resistance: 2400 hours of salt spray test, no intergranular corrosion

- Low-temperature toughness: -50 ℃ impact function retention rate of > 92%

- Welding without preheating: MIG/TIG welding crack rate <0.3%.

- Electromagnetic compatibility: magnetic permeability <1.05μH/m (special for radar equipment area)

- Lightweighting benefits: density 2.66g/cm³, 58% weight reduction instead of steel

- Freedom of molding: Cold bending radius up to 3 times the thickness (ISO 209 standard)

- Environmental certification: in line with IMO 2025 marine materials recyclability requirements

Aluminium angle bar marine grade 5086 is widely used in a number of key areas in the shipbuilding process. For example, it can be used to manufacture the reinforcement of the deck edge, where it needs to withstand greater wind and wave impacts; it can also be used to construct the side panels of the ship's side, which play a role in protecting the ship's hull from the erosion of the external environment. In addition, it can also be found in the internal structure of the ship, such as bulkheads and bulkheads, providing the necessary support and stability for the entire ship's hull.11 Due to its excellent welding properties, Grade 5086 angle aluminum can also be perfectly combined with other metal parts, further enhancing the overall structural strength of the ship's hull.

In summary, with its excellent mechanical properties and adaptability, aluminium angle bar marine grade 5086 has become an indispensable part of the modern shipbuilding industry. Whether from the technical point of view or economic benefits, choosing 5086 marine grade aluminum angle bar is a wise choice. If you are looking for an ideal material that can both improve ship performance and reduce maintenance costs, consider this high-performance aluminum alloy product. Through strict quality control and expert manufacturing processes, we offer aluminum angle bar 5086 marine grade that will help your project ensure that every vessel can safely and efficiently navigate the vast oceans.