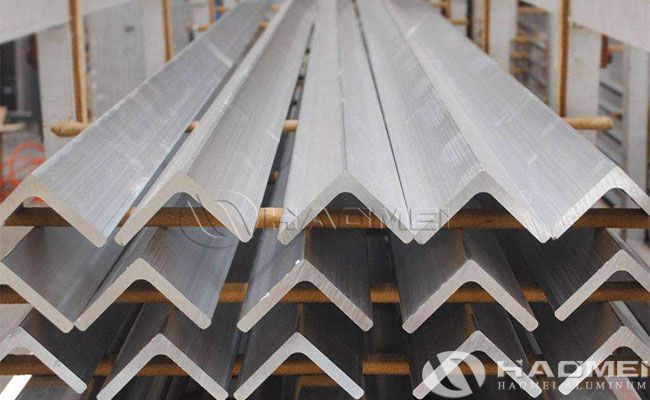

Marine Grade Angular Aluminum High Quality

Marine grade angular aluminum is a kind of aluminum alloy material with specific shape, whose cross-section is usually L-shaped or angle-shaped. This material not only inherits the excellent properties of aluminum such as light weight, corrosion resistance, electrical conductivity and thermal conductivity, but also has high strength and good plasticity due to its special shape. As a high-quality marine material, marine grade angular aluminum plays an important role in the field of shipbuilding and ocean engineering. Marine grade angular aluminum is generally made of aluminum alloys, such as 6061, 6082 and other series, these aluminum alloys have good strength, corrosion resistance and machinability, which are suitable for marine environment. Angular aluminum alloys usually undergo different heat treatment states, such as T6 state (after dissolution treatment and aging treatment), to improve their mechanical properties and corrosion resistance.

Characteristics of Marine Grade Angular Aluminum

- High strength and light weight:

Marine grade angular aluminum has excellent strength to weight ratio, its density is much lower than steel, but the strength can meet the needs of shipbuilding. This lightweight and high-strength characteristics make marine grade angle aluminum an ideal choice for reducing ship weight and improving fuel economy.

- Excellent corrosion resistance:

Marine grade aluminum angular is often specially alloyed to enhance its corrosion resistance. In the marine environment, aluminum reacts with oxygen in the air to form a dense film of aluminum oxide, which effectively resists salt and other corrosive substances in seawater.

- Good welding performance:

Marine grade aluminum angle has good welding performance, easy to weld connection with other aluminum or steel. The performance of the welded joints is stable and not easy to crack or deform, which ensures the overall strength and stability of the ship structure.

- Easy processing and molding:

Marine grade aluminum angle has good ductility and plasticity, easy to be processed into various shapes and sizes by cold or hot working. This makes marine-grade aluminum angular flexible for use in the construction of complex structures in shipbuilding.

- Good electrical and thermal conductivity:

Marine grade angular aluminum has good electrical and thermal conductivity, which is critical for electrical and heat exchange systems on ships. It helps to ensure the normal operation of the electrical system and the safe operation of the ship.

The application scope of marine grade angular aluminum:

- Ship Structure:

Marine grade angular aluminum is widely used in the frame structure, deck, bulkheads and other key parts of ships. Its high-strength and lightweight characteristics make the ship structure more robust and durable, and at the same time reduces the weight of the ship and improves the fuel economy.

- Marine Equipment:

Marine grade aluminum angular is also used in the manufacture of various equipment on ships, such as masts, rudder wheels, anchor chains and so on. These devices need to withstand great tension and pressure, and the high strength and corrosion resistance of marine-grade aluminum angle can meet these requirements.

- Marine interiors:

Marine grade angular aluminum is also commonly used in the interior decoration of ships, such as floors, ceilings, walls and so on. Its beautiful appearance and easy-to-clean characteristics make the ship's interior environment more comfortable and tidy.

- Marine Engineering:

In addition to shipbuilding, marine grade aluminum angular is also widely used in the field of marine engineering, such as offshore platforms, submarine pipelines and so on. Its excellent corrosion resistance and lightweight and high-strength characteristics make marine-grade aluminum angle an important material in the field of marine engineering.

To sum up, marine grade angular aluminum plays an important role in the field of shipbuilding and ocean engineering with its high strength, light weight, excellent corrosion resistance, good welding performance and easy processing and forming. It has a wide range of applications, from ship structure to ship equipment to ship interiors and ocean engineering, showing its unique advantages and value.