Aluminum Clad Steel Plate

- Types: Aluminum/steel clad plate

- Main materials: 1A97,1A93,1A90,1A85,1070,1060,5083

- Q235B.CCSB.Q245R.Q345R

- 15CrMoR,16Mn,20MnMo,15CrMo

- 109MnNiDR,16MnD,09MnNiD

- Introduction

- Feature

- Application

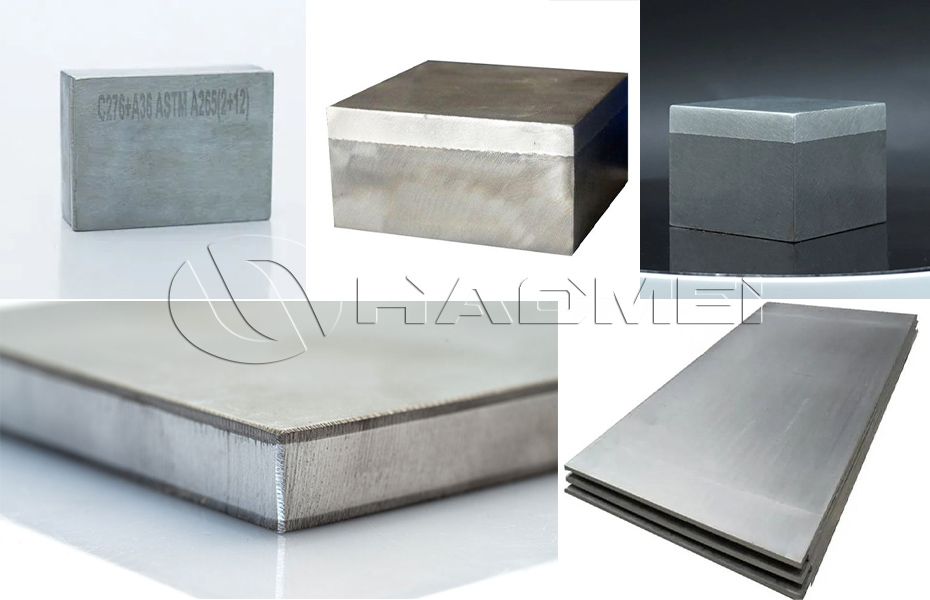

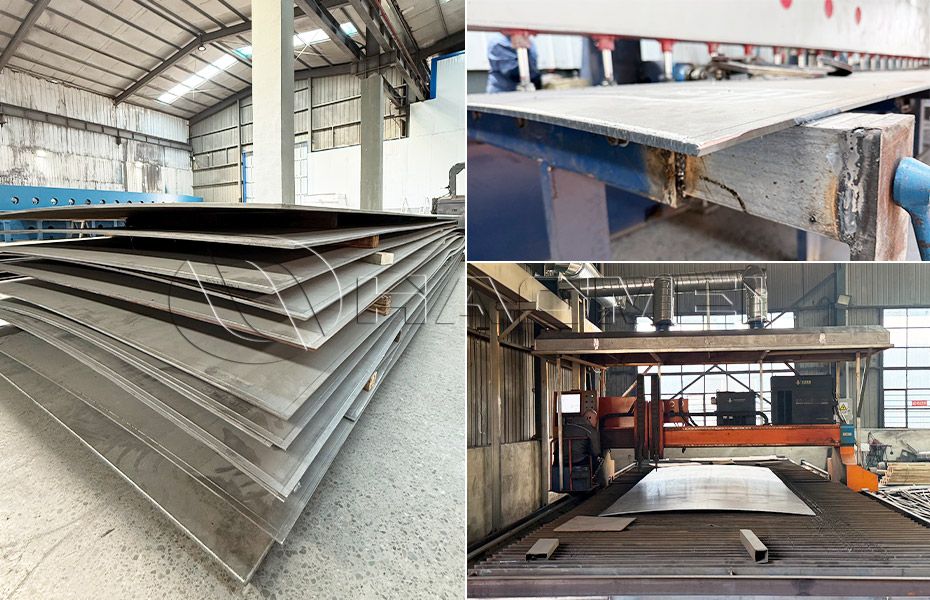

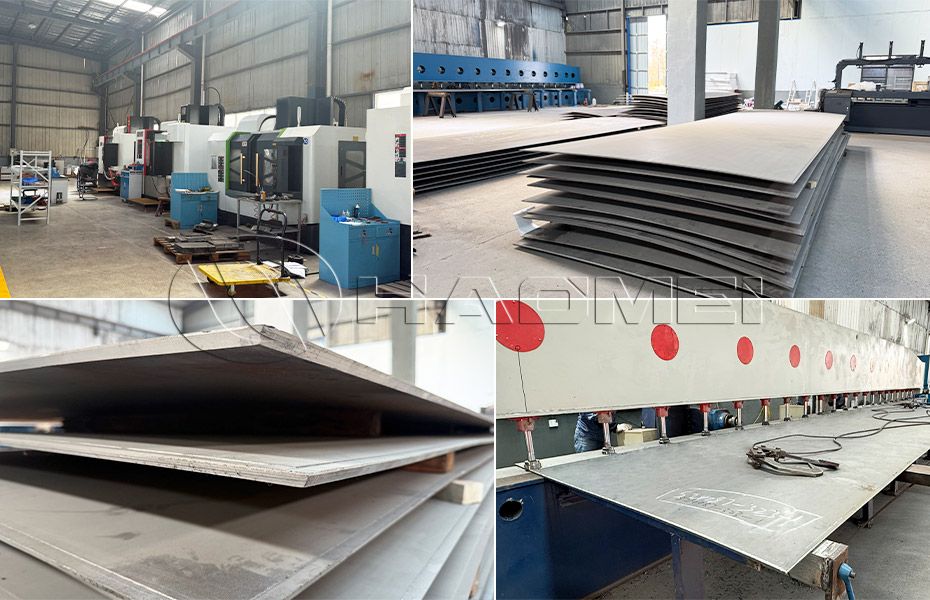

- Pictures

- Video

- Download

What is Aluminum Clad Steel?

Aluminum clad steel is a composite material where a layer of aluminum is bonded to a steel core by explosive welding.

This process creates a material that combines the high tensile strength of steel with the corrosion resistance of aluminum.

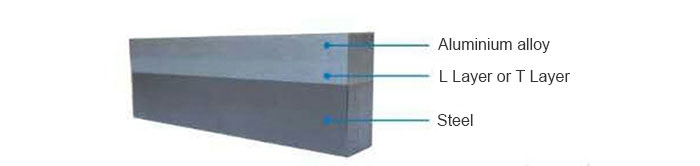

Structure of Aluminum Clad Steel:

Specification of Aluminum Steel Clad Plate:

Types of products

| Main materials

| Product specifications (mm) | Product standard | Application area

|

Aluminum/steel clad plate

| 1A97,1A93,1A90,1A85,1070,1060,5083 Q235B.CCSB.Q245R.Q345R 15CrMoR,16Mn,20MnMo,15CrMo 109MnNiDR,16MnD,09MnNiD | 1-14/6-80x <1000x<4000

| GBT 8546-2007 | Electrolytic aluminum, transition joints, nava vessels,aerospace,instrumentation,cryopenic engineering, etc |

Product Type | Aluminum Steel Clad Plate |

Clad Metal | Aluminum (Al) |

Base Metal | Steel (typically mild steel or carbon steel) |

Clad Thickness | Typically 1.0 mm to 10 mm (depending on the application) |

Overall Plate Thickness | Ranges from 6 mm to 100 mm |

Clad Layer | Typically 10% - 30% of the total plate thickness |

Bonding Method | Roll bonding, Explosion bonding, or Laser cladding |

Bond Strength | High bond strength (comparable to base material) |

Mechanical Properties | |

Tensile Strength (Base Steel) | 400-550 MPa (varies with steel grade) |

Tensile Strength (Clad Aluminum) | 150-300 MPa (varies with alloy type) |

Yield Strength (Base Steel) | 250-450 MPa (depends on steel grade) |

Yield Strength (Clad Aluminum) | 100-200 MPa (depends on aluminum alloy) |

Hardness (Base Steel) | 120-250 HV (varies with steel type) |

Hardness (Clad Aluminum) | 40-110 HB (depends on alloy and temper) |

Thermal Conductivity | 100-150 W/m·K (Aluminum Clad Side) |

Corrosion Resistance | Excellent (Aluminum side provides corrosion resistance) |

Density | 2.7 g/cm³ (Aluminum) + 7.85 g/cm³ (Steel) |

Electrical Conductivity | Aluminum side offers good electrical conductivity |

Applications | Marine, Chemical Industry, Heat exchangers, Electrical contacts, Automotive |

Welding Compatibility | Compatible with both Aluminum and Steel welding techniques (e.g., MIG, TIG) |

Formability | Good formability for both Aluminum and Steel sides |

Surface Finish | Can be supplied in various finishes (polished, brushed, mill finish) |

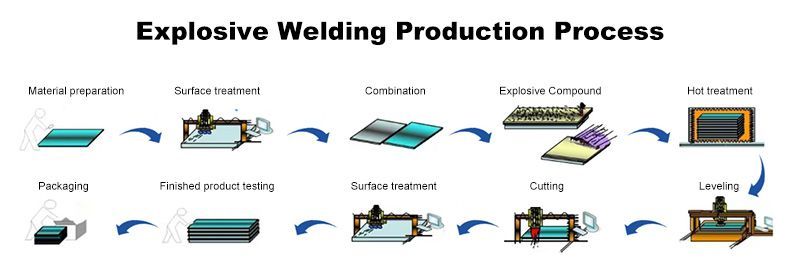

Processing of Aluminum Clad Steel Plate:

Certificate of Aluminum Steel Clad Plate:

FAQs of Aluminum Steel Clad Plate:

Q:What is aluminum clad steel?

A:Aluminum clad steel wire, often abbreviated as AW or AS or AC, is an electrical conductor consisting of an inner steel core and an outer aluminum cladding. Aluminum clad steel wire is a bimetallic material in which aluminum is continuously and evenly coated on a steel core.

Q:What does stainless steel aluminum clad mean?

A:What does "clad" mean? Cladding is a technique for making cookware. It involves layering sheets of metal and bonding them together. The most common is sandwiching sheets of aluminum (or copper) between sheets of stainless steel.

Q:What is clad steel plate?

A:Clad steel plates are made by joining various metals such as stainless steel and aluminum, titanium and aluminum, etc., depending on the application. We have successfully developed wide-strip roll-joining technology and established a system for mass production of high-quality clad products.

Features of Aluminum Steel Clad Plate:

- Light weight:

The weight of the aluminum steel clad plate is only about 1/3 of the traditional pure aluminum plate, so it can greatly reduce the load of the building and reduce the structural cost.

- Corrosion resistance:

The surface of the aluminum steel clad plate has good corrosion resistance, which can effectively prevent the erosion of buildings by corrosive gases such as acid rain and salt spray.

- High strength:

Aluminum steel clad plates have very high strength and can be made into various structural parts or parts with complex shapes, uneven thickness and large loads.

- High temperature resistance:

Aluminum steel clad plates can withstand high temperatures up to 1000°C, so they are very useful in many high temperature applications.

- Wear resistance:

The wear resistance of aluminum steel clad plates is very good, it can effectively reduce friction, reduce wear and prolong the service life of buildings.

- Fatigue resistance:

Due to the low elastic modulus and good toughness (elongation greater than 25%) of the aluminum/steel clad plate, it has good shock resistance and has a good absorption effect on impact loads.

Aluminum steel clad plates have been widely used in construction, aviation, transportation, electronics, medical and other fields.

Specific applications include:

- Construction:

Aluminum steel clad plates can be used for building exterior walls, interior partitions, stair railings, door and window frames, etc., due to their light weight, corrosion resistance, high strength, high temperature resistance, wear resistance, fatigue resistance, and good self-lubricating properties And other advantages, can improve the safety, comfort and durability of buildings.

- Aviation:

Aluminum steel clad plates are one of the important structural materials for aircraft, rockets and other aircraft. Due to their lightness, high strength, high temperature resistance, and corrosion resistance, they can improve the load capacity and safety of aircraft.

- Transportation:

Aluminum/steel clad plates can be used to manufacture automobile bodies, railway carriages, ship decks, rolling stock, aviation equipment, etc. Due to their light weight, high strength, and corrosion resistance, they can improve the load-carrying capacity and safety.

- Medical aspects:

Aluminum steel clad plates can be used to manufacture medical device shells, such as medical beds, medical carts, operating tables, etc. Due to their light weight, high strength, and corrosion resistance, they can improve the service life and safety.