Aluminum Steel Transition Joint Marine Grade For Shipbuilding

- Standard: GB/T2968-90, ASTM, ASME, AMSE, MIL, JIS, DIN,EN

- Certificate: ISO9001:2008;CCS, BV

- Material: Marine Grade Aluminum 5083+Aluminum+Steel Or Customized Materials

- Cladding metal thickness: 0.5~50mm

- Base metal thickness: 0.5~500mm

- Introduction

- Feature

- Application

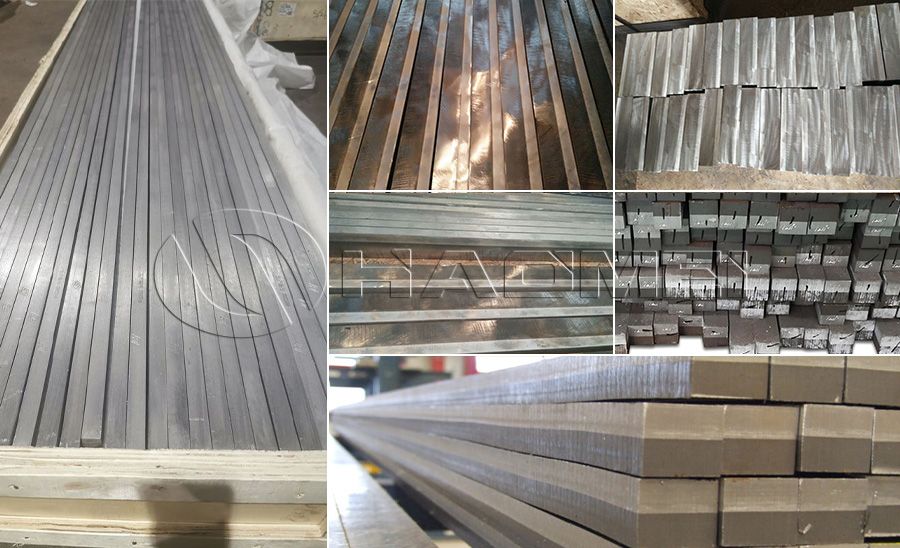

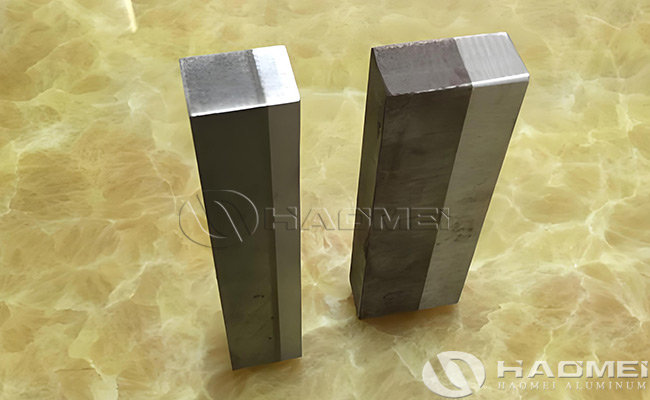

- Pictures

- Video

- Download

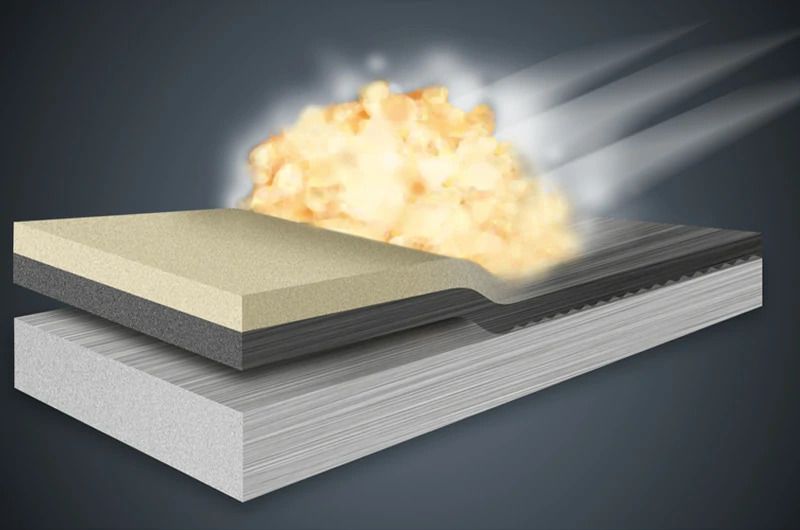

Aluminum steel transition joint is a high-quality material that uses explosive welding technology to weld aluminum and steel, most commonly used in shipbuilding as a transition joint for hull structures.

The structural transition joints are manufactured by vacuum explosion welding process, this high quality material boasts superior joint strength for rigorous maritime applications. The explosion welding performed in a vacuum environment provides improved protection from corrosive environments.

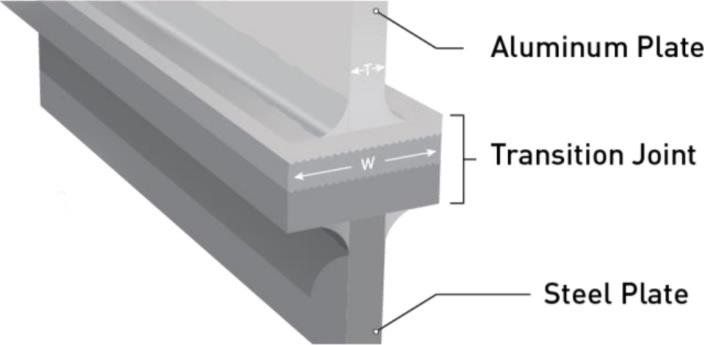

Structure of Aluminum Steel Transition Joint:

Aluminium/steel transition joint is generally composed of a three-layer structure: steel, pure aluminum and seawater resistant aluminum alloy. The three layers are evenly bonded together using explosive welding technology. The specific parameters of each layer of material are:

Base Material: Steel (SS41)

Base Material: Steel (SS41)

Middle layer - intermediate: pure aluminum (1050A)

Surface layer - cladding material: 5083 aluminum alloy, etc.

Specification of Aluminum Steel Transition Joint:

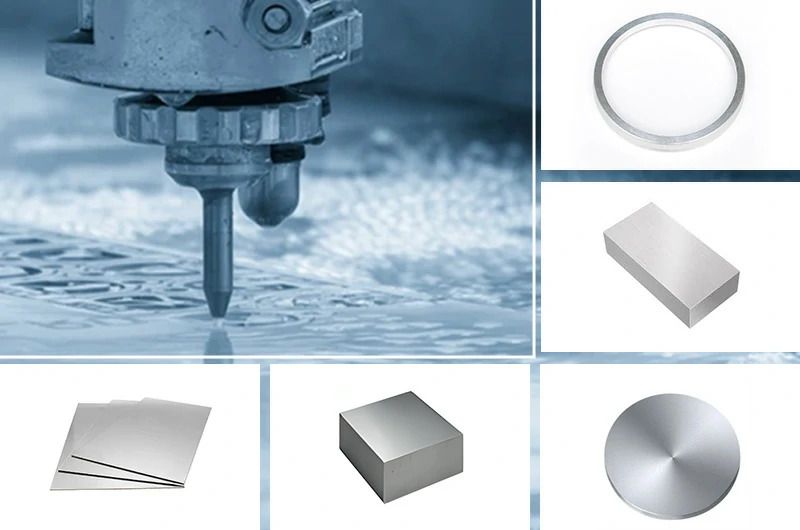

Haomei manufactures structural transition joint using standard mother plates of 1300 x 3800mm, with a maximum size of 4 x 12 meters and thickness ranging from 1mm to 100mm. After saw cutting or water jet cutting, these joints can be customized into various shapes and sizes, including plates, blocks, discs, rectangles and rings.

We offer customized transition joints with various metal interlayers, shapes, and sizes based on customer requirements. With short lead times, we ensure that clients can meet their project demands on time.

Steel | Interlayer | Aluminum alloy | Thickness (mm) |

Steel SS41 Grade B | 1050 | 5083 | 28(18+4+6) |

Shipbuilding steel Grade D | 1050 | 5083 | 28(15+3+10) |

Shipbuilding steel Grade D | 1050 | 5083 | 33(20+3+10) |

Marine plate Grade A | 1050 | 5083 | 28-34 |

A516-55 | 1050 | 5086 | 34.5(19+9.5+6) |

A516-55 | 1050 | 5083 | 19(10+5+4) |

A516-55 | Grade 1 titanium | 3003 | 31.5(19+1.5+10) |

A516-55 | 1100 | 5086 | 19.05(9.525+6.35+3.175) |

A516-56 | 1100 | 5456 | 34.925(19.05+9.525+6.35) |

Stainless steel 316L | Grade 1 titanium | 3003 | 31.5(20+1.5+10) |

Stainless steel 316L | 1100 aluminum Grade 1 titanium N02200 nickel | 5086 | 24(9.5 +6.5+2+3+3) |

Stainless steel 316L | 1100 aluminum Grade 1 titanium N02200 nickel | 5456 | 31(19+9.5+2+3+6.5) |

Mechanical Properties of Aluminum/Steel Transition Joint:

Our structural transition joint offer exceptional mechanical properties, ensuring strong and reliable connections!

Mechanical properties | Data |

Shear strength - Basemetal/Intelayer | >55N/mm² |

Tensile strength (through thickness) | 75N/mm² |

Processing temperature | Max 315℃×30min |

Bend test base material in compression | Acceptable |

Bend test base material in tension | Acceptable |

Side Bend Test | Acceptable |

Why use Aluminum Steel Transition Joint in Shipbuilding?

Aluminum and steel have vastly different coefficients of thermal expansion. The three bonded layers of transition joint function as an intermediary union between the steel and the aluminum and withstand corrosive seawater.

Structural Transition Joints are used in shipbuilding because:

- It saves weight

- Exploits the best properties of both materials

- Is resistant to corrosion

- Has a great tensile strength

- Has a great fatigue resistance

Testing and Quality Control of Aluminum/Steel Transition Joint:

To ensure the superior performance and long-term reliability of structural transition joint, we implement strict testing procedures, covering every stage of production from raw materials to finished products.

- 100% Ultrasonic Testing (UT): Ensures each product is free from internal defects and meets thickness requirements.

- Penetrant Testing (PT): Uses dye penetration to effectively detect micro-cracks and surface flaws.

- Dimensional Inspection: Every structural transition joint undergoes precise measurement checks.

- Raw Material Testing: Ensures materials meet specific specifications, guaranteeing quality from the source.

- Torsional Fatigue Test: Evaluates the joint’s durability under long-term torsional stress.

- Tensile/Compression Fatigue Test: Simulates real-world tensile and compression forces to assess fatigue life.

- Shear Stress Test: Verifies the joint’s ability to withstand various stress conditions.

- Flatness Test: Ensures precise installation and interchangeability.

Welding Method of Aluminum/Steel Transition Joint:

Replacing traditional rivet and nut-and-bolt and attachments with alu-steel transition joints will reduce the risk of corrosion when attaching a steel hull to an aluminum superstructure. Transition joints can be welded with most of the traditional methods used on both parent materials including:

GTAW

GMAW

TIG

MIG

Aluminium/steel Transition Joint Welding Precautions:

(1) Welding is not allowed within 3mm of the aluminum steel interface.

(2) The steel-aluminum interface temperature is kept below 300 °C.

(3) The interlayer temperature shall not be higher than 200 °C.

(4) The transition joint cannot be preheated.

(5) Gas-cutting is not allowed for transition joints, only mechanical cutting.

Frequently Asked Questions About Aluminum Steel Transition Joint:

Q: Why is it necessary to weld aluminum to steel in shipbuilding?

A: Composite metals and structural transition joints are mainly used in the shipbuilding industry. The hull is typically made of steel, while other parts are constructed with aluminum.

Q: How do transition joints accommodate the different expansion coefficients of aluminum and steel?

A: With transition joints, force is evenly distributed rather than being applied at specific points like in mechanical joints. This ensures that all stresses remain within the shear load capacity.

Q: I operate in extremely harsh conditions. Are there other transition joints suitable for my application?

A: Yes, we also manufacture joints with a titanium layer, which are particularly suitable for LNG storage tanks or environments where welding temperatures may be elevated.

Q: What is the lifespan of an structural transition joint?

A: Under normal ship operating conditions, its lifespan fully matches the service life of the hull structure.

Q: What are the cost advantages of structural transition joint?

A: The initial purchase cost may be slightly higher than traditional connection methods, but in the long run, it offers significant overall cost savings, providing a higher return on investment.

Advantages of Aluminium/Steel Transition Joint:

- No maintenance required after installation, reducing long-term repair, refurbishment, and replacement costs.

- Ensures a continuous joint with even stress distribution at the connection.

- Offers excellent waterproof performance, minimizing the risk of corrosion.

- Supports lightweight ship design, improving overall efficiency.

- Manufactured using vacuum explosive welding, preserving the original metallic properties and ensuring high joint strength.

- Cost-effective by layering thin, expensive materials over thicker, more affordable ones.

- Achieves the desired cladding thickness in one step, with a smooth surface, reducing post-processing requirements.

- Compared to traditional bolted and riveted connections, structural transition joint provide superior strength, corrosion resistance, easier installation, and lower maintenance needs.

Applications of Aluminium Steel Transition Joint:

Structural transition joints are used for welding aluminum to steel in shipbuilding and large-scale offshore projects like oil platforms. In the manufacture of marine vessels, the application of aluminum alloys is mainly to connect the aluminum structural members to the steel deck. The transition joint also connects the aluminum superstructure, mast and antenna to the steel hull. This will reduce the ship's center of gravity and enhance the stability of the ship.

- Connecting aluminum superstructures to steel decks.

- Joining aluminum decks and bulkheads to steel hulls.

- Installing windbreak decks on steel ships.

- Creating permanent joints between steel (or stainless steel) and aluminum for components like pillars and partitions.

- Upgrading containerized electronic equipment to steel decks.

- Attaching steel components to aluminum hulls.

- Providing wear-resistant keels for aluminum vessels.

- Installing helicopter decks on ships or offshore drilling platforms.

- Mounting aluminum walkways or accommodation modules on offshore drilling platforms.