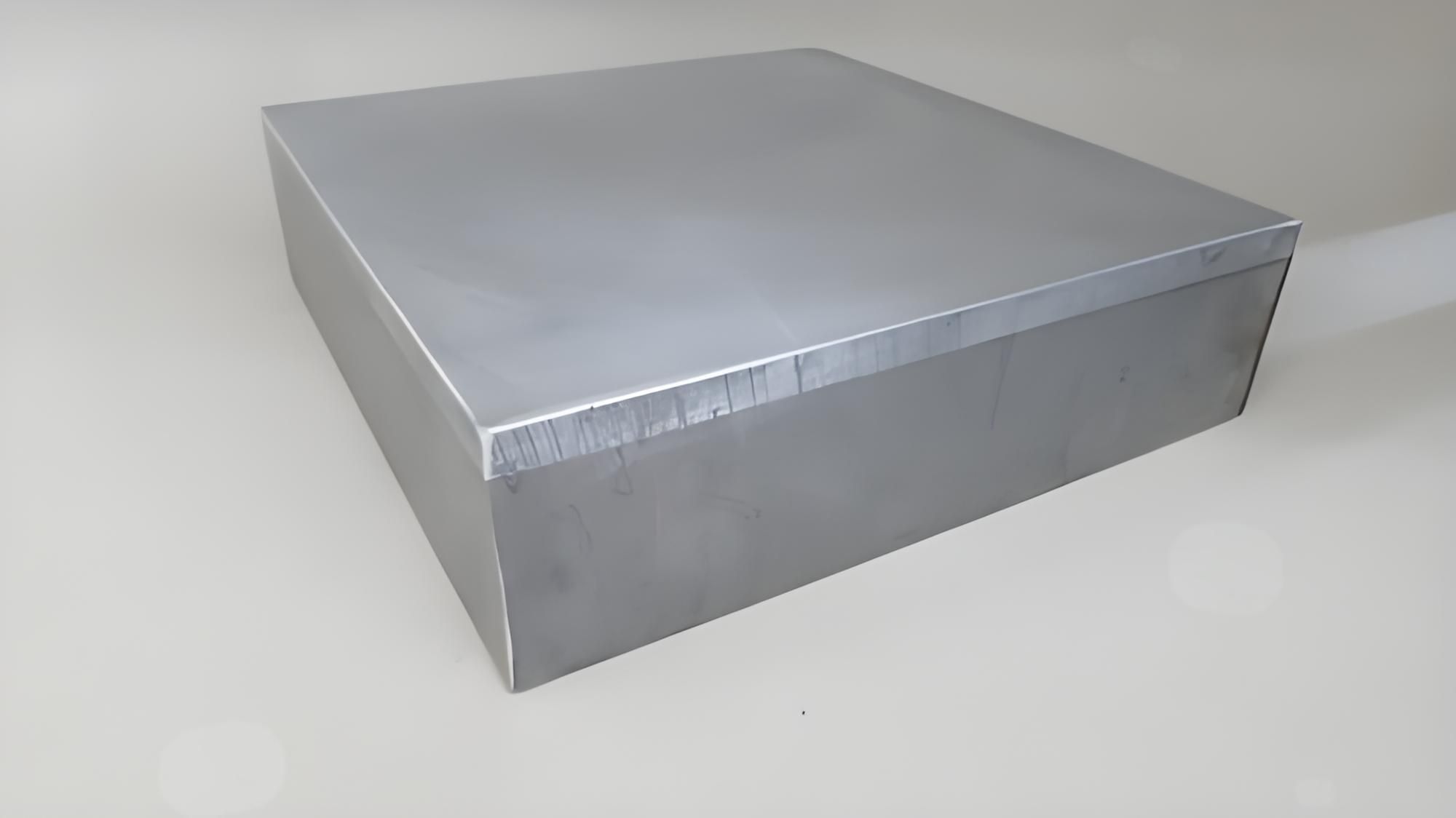

Aluminum Clad Steel Plate For Shipbuilding

Aluminum clad steel plate for shipbuilding are dissimilar metal composite materials that combine aluminum (or aluminum alloy) and steel (or low-alloy steel) through specialized processes such as explosive welding and roll-bonding. They utilize a steel base layer for structural strength and an aluminum (or aluminum alloy) cladding layer for corrosion resistance and lightweighting. This creates a synergistic advantage of "strength, corrosion resistance, and lightweight" specifically tailored to the complex demands of ships operating in marine environments.

The key advantages of aluminum clad steel plate in shipbuilding stem from their following key features, which perfectly match the core requirements of shipbuilding:

1. Balanced Lightweight and High Strength

With a density of only about one-third that of steel, the aluminum layer in the composite panel significantly reduces the weight of the ship (by 20%-30% compared to a pure steel structure), thereby reducing fuel consumption, increasing speed, or increasing cargo capacity. At the same time, the steel base layer provides sufficient structural strength and rigidity to meet the ship's mechanical requirements for pressure resistance and impact resistance (such as wave loads), resolving the contradiction between the insufficient strength of pure aluminum and the excessive weight of pure steel.

2. Excellent Marine Corrosion Resistance

The marine environment is characterized by high salt spray and humidity, making it extremely corrosive to materials. Aluminum (or aluminum alloy) forms a dense oxide film (Al₂O₃) in the air, effectively resisting corrosion from seawater and salt spray. The aluminum layer completely encapsulates the steel substrate, preventing direct contact with corrosive media and significantly reducing the risk of steel rust. Compared to pure steel structures, which require frequent painting and maintenance, aluminum-steel clad panels reduce corrosion protection costs and maintenance cycles, extending the lifespan of the vessel.

3. Balancing Economy and Practicality

Pure aluminum or aluminum alloys are relatively expensive (especially the high-grade aluminum required for large hulls). While pure steel is cheaper, it suffers from poor corrosion resistance and excessive weight. Aluminum clad steel plate use steel as the main component (to reduce costs) and aluminum only on the surface (to control corrosion resistance costs). While achieving performance close to that of an all-aluminum structure, they are significantly cheaper than all-aluminum solutions, offering a more cost-effective solution.

4. Good Process Adaptability

Aluminum clad steel panels can be connected to other hull structures (such as steel frames) through conventional processes such as welding and riveting, making construction less difficult than all-aluminum structures. Furthermore, their mechanical properties (such as fatigue resistance and toughness) are well-suited to the repeated stresses a ship experiences in waves, providing enhanced stability.

In summary, the combined advantages of "strong steel, lightweight aluminum, and corrosion resistance" make aluminum clad steel plate an ideal material for balancing safety, econom, and endurance. They are widely used in key areas such as hull hulls, decks and cabins in shipbuilding.